Polybutylene pipes, although they seemed like a miracle product that was both flexible and strong, experienced massive failures a decade or so after installation in many homes. Failure is inevitable, so even if pipes have lasted a little longer, they are bound to start causing issues.

There’s no point in stressing if your pipes are not made of polybutylene, and if you know that they are, then you can take steps to mitigate or eliminate the risk. This is where pipe identification comes in. Once you or a pipe inspector makes the determination that your home has polybutylene pipes, you must consider the many pros and cons to decide whether you’ll keep or replace these pipes.

Polybutylene pipes can be identified by a professional or by locating a PB2110 code on the pipes. They can also be identified by color (most often gray), flexibility, size (0.5-1"), year of installation (1978-2005), and location (water supply lines, not drain, waste, or vent pipes).

Hire a Professional Inspector

If you are worried that your home has polybutylene pipes and would like a professional to either confirm or deny this, it is best to call a pipe inspector.

A pipe inspector focuses on the engineering part of the plumbing. They specialize in locating leaks and other defects in pipes.

Not only will a pipe inspector be able to identify different types of plumbing, including polybutylene pipes, but they would also be able to locate other faults in your piping, such as cracks.

Polybutylene could be identified by a pipe inspector and your pipes would also get a wellness check of sorts.

In order to find a pipe inspector, simply look up “pipe inspector near me” or a similar search in your desired search engine, and a nearby service should appear.

It is important to note that most plumbers should also be able to identify polybutylene pipes for you.

General contractors, on the other hand, may not have expertise in plumbing and may not be qualified. If you would like to hire a general contractor for this job, be sure to inquire about their experience with plumbing and polybutylene pipes first.

What Pipes to Look At

If you plan to inspect your pipes yourself, it is very important to know where to look to save yourself some time.

Polybutylene pipes were only used as supply pipes and never as drain, waste, or vent pipes. As such, all non-supply pipes in your home do not have to be inspected since they are undoubtedly not polybutylene.

As far as what appliances these kinds of pipes supplied, they often supplied the water heater, toilets, and sinks.

They are also often running across the ceiling of unfinished basements.

In the home, polybutylene pipes are supply-only pipes located near water heaters, toilets, sinks, and sometimes running along the ceilings of unfinished basements.

As far as outside the home, it was common to have polybutylene pipes at the beginning of the piping, near the water meter, and where the pipe enters your home, which is often through a basement wall or near the water heater.

The rest of the underground pipe may be copper or the entire pipe may be polybutylene.

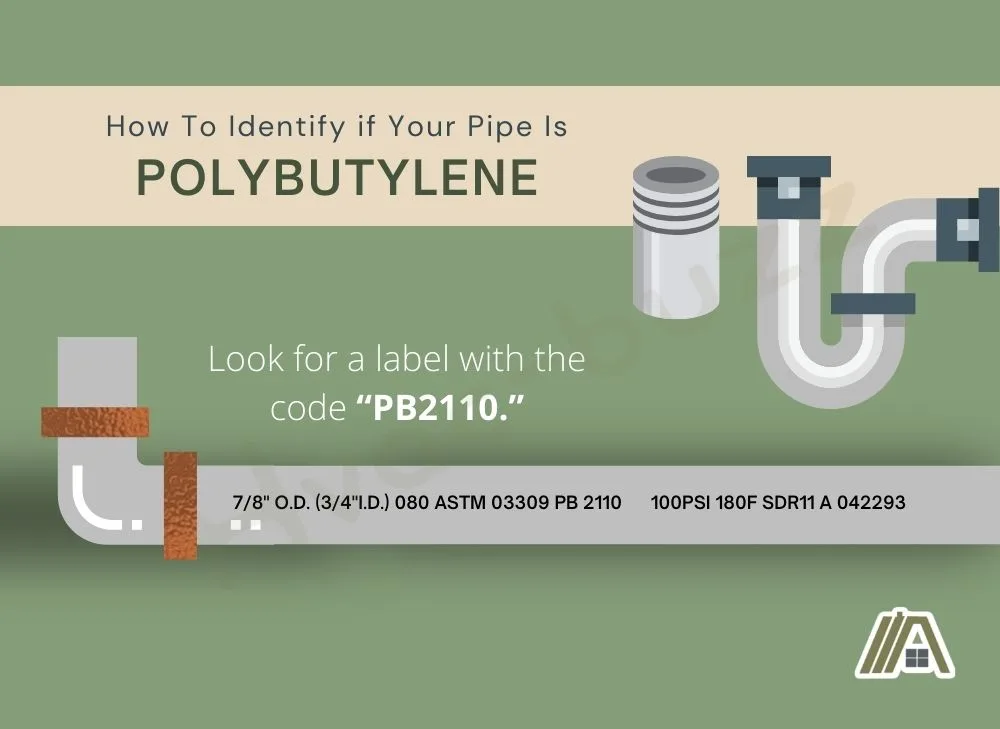

Look for a Label on the Pipes

To confirm that a pipe is polybutylene, you can look for a label only used by this kind of pipe. This label is the code “PB2110.”

It will often be located length-wise on the pipes, meaning the code runs with the length and does not wrap around the circumference of the pipe.

The text is often black or white.

It may be harder to spot since the label often has a serial number or another type of code before and after it. The code will most likely not be isolated on the pipe.

If you find this exact code on the label of the pipe, the pipe is sure to be polybutylene.

When Was Your Plumbing Installed/Upgraded?

Your home might be completely safe from the failure of polybutylene pipes if its plumbing was installed or upgraded before, during, or after certain years.

Using this information can help you to determine whether your pipes are polybutylene.

The timeline of polybutylene pipes began in 1978 when the use of polybutylene pipes took off because of their low cost and flexibility.

In the 80s and early 90s, polybutylene continued to be used in most of the US, despite some lawsuits during this time period.

By 1995, though, it was very rare for polybutylene pipes to be used due to the general public and businesses’ awareness of their failure, as well as many lawsuits.

So, if your plumbing was last updated or installed before 1975, there won’t be any polybutylene pipes in your home. This is because they were not introduced to the market during this time.

If your plumbing was updated or installed after 1995, it is unlikely that you will have polybutylene pipes but since the phasing out of the material wasn’t complete yet, there is still a chance.

After 2005, I can nearly guarantee that your home does not have polybutylene pipes since they were completely phased out of the market at this point. In Canada, they are banned and in the US, they are no longer sold.

If your plumbing was installed or updated any time between 1975 and 1995, though, there is a chance that polybutylene pipes were used.

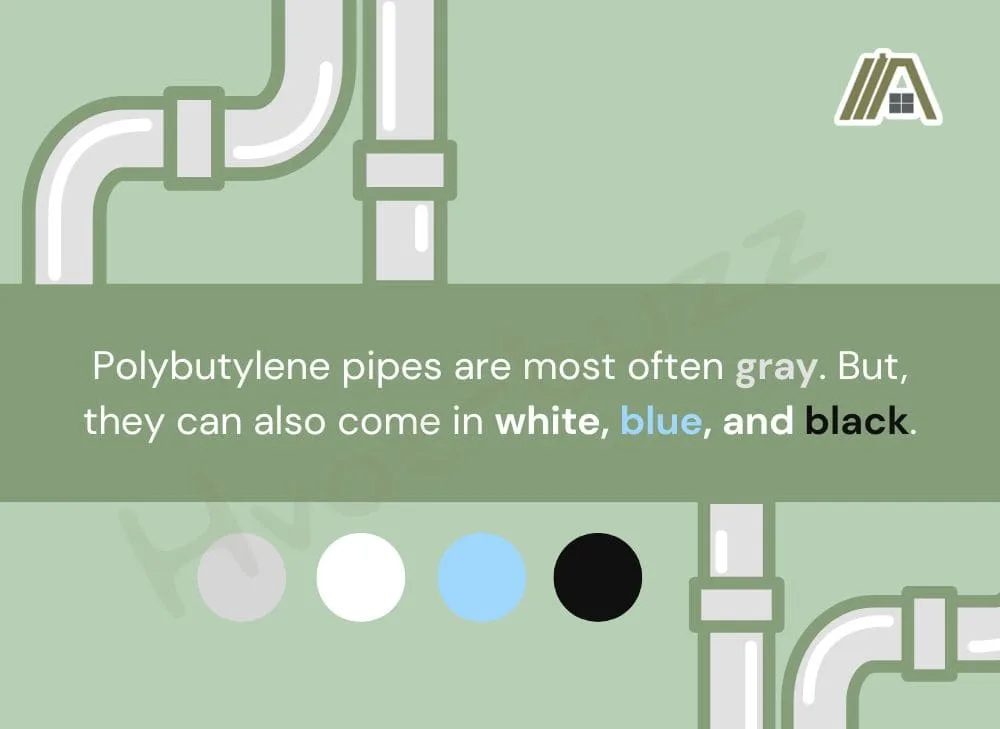

Check the Color

Another easy way to identify polybutylene pipes is by color. Polybutylene pipes are most often gray. But, they can also come in white, blue, and black.

This color is solid and the entire length of the pipe would be the same color.

As copper pipes are a common alternative to polybutylene pipes, this means that if you see copper/gold/red-ish pipes, they are not going to be polybutylene.

If, however, your pipe seems to be a type of plastic and is one of the aforementioned colors, though, that does not mean it is polybutylene. For example, ABS pipes are black and PVC pipes are always white.

More details about the pipes must be studied before making your determination.

Are they Flexible/Curved?

A characteristic that is unique to polybutylene pipes is their flexibility. Other plastic pipes are much more rigid, as is copper.

Polybutylene’s flexibility made for easier installation, and this flexibility can be used to identify the pipes since rigid piping cannot curve the way polybutylene can.

If you are only looking for flexibility, though, you may confuse flexi hoses for polybutylene pipes.

Flexi hoses are rubber and stainless steel pipes that are very flexible. Flexi ducts can be used in a variety of places, and flexi hoses can too. Most commonly, though, they supply water to sinks and toilets, much like polybutylene pipes.

An easy way to tell these two apart is to look for ridges. The many ridges of flexi hoses are what allow them to bend so easily. Polybutylene pipes will not have these ridges.

What Size Are the Pipes?

The size of plumbing pipes often ranges from 0.5″ to 24″ in diameter.

Polybutylene pipes’ size falls on the lowest side of the spectrum, with their diameter often being 0.5-1″.

The small size of polybutylene pipes can aid in the identification of them.

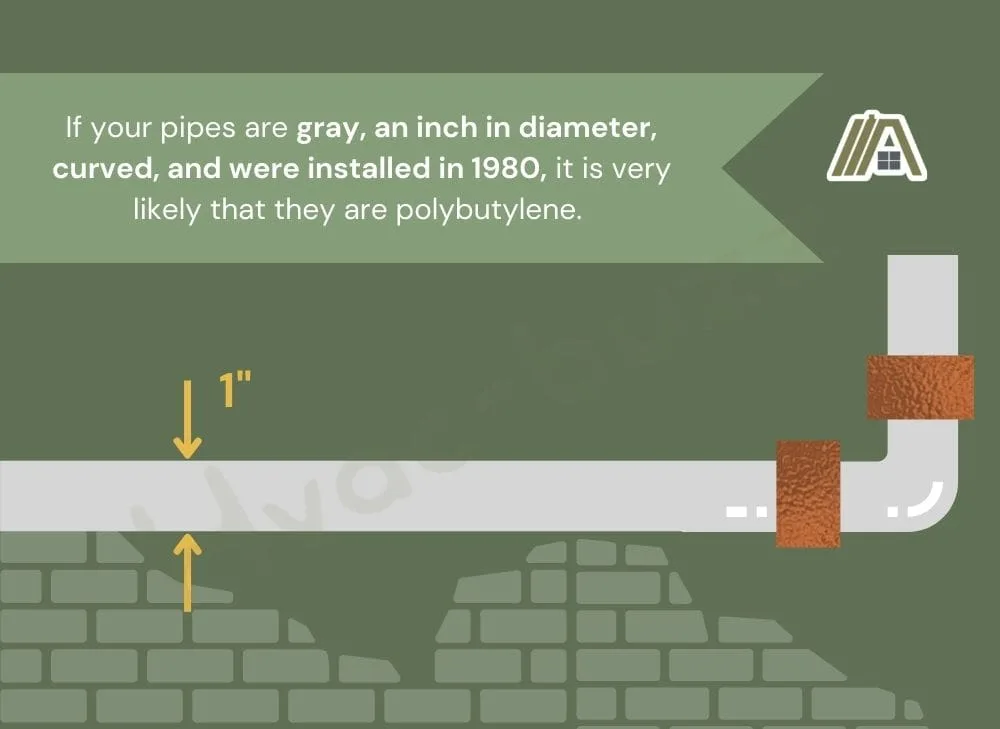

Look at the Factors Together

If a hired expert tells you that your pipes are polybutylene or if you find the “PB2110” label on your pipes, this pretty much guarantees the likelihood of polybutylene pipes in your home.

Without these tests, however, using just one of the characteristics of polybutylene to identify your pipes cannot guarantee if you have polybutylene pipes like a label or professional can.

If your pipes are small, this does not mean they are polybutylene. Similarly, if you know your plumbing was installed in 1980, this does not mean your pipes are polybutylene.

However, if your pipes are gray, an inch in diameter, curved, and were installed in 1980, it is very likely that they are polybutylene.

All of the determining factors must be considered to accurately determine if your pipes are polybutylene.

Even if your pipes aren’t gray, but everything else checks out, the pipes may still be polybutylene.

If each identifier of polybutylene is a box in a checklist, the majority of these identifiers must be checked for the pipes to be accurately labeled as polybutylene.

Do You Have to Replace the Pipes?

Although polybutylene piping is no longer used in modern plumbing in North America, it is not illegal to have this type of plumbing in your home.

You are not obligated to repipe your home if it is found to have polybutylene pipes, but it is very highly recommended.

The pros of replacing polybutylene piping include:

- Your home should be safe from extensive water damage from polybutylene pipe failure.

- Selling your home will not be hindered by the presence of polybutylene pipes.

- You won’t have to deal with your insurance raising your premium or not renewing your policy to cover damages from the polybutylene pipes.

- The pipes that the polybutylene is replaced with will have a much longer lifespan.

The cons of replacing polybutylene piping include:

- Semi-invasive plumbing work will occur in your home for around five business days.

- Complete repiping will be expensive.

- Although you don’t have to pull the permit for any project, the plumber or contractor will, which can take time.

If you are not selling your home any time soon and cannot afford to repipe your home, or even if you would rather wait until the pipes fail to replace them, you may choose to leave them in.

The pros of leaving the polybutylene piping include:

- You won’t have to pay for the repiping.

- If your pipes haven’t failed yet, it may be a few years until they do.

- You won’t have to deal with invasive plumbing work in your home or wait for a permit to be approved.

The cons of leaving the polybutylene piping include:

- You’ll likely have difficulties selling your home (you have to disclose polybutylene pipes).

- You may have to spend thousands of dollars on water damage if you do not have insurance.

- If you do have insurance, they may raise your premium or won’t renew your policy.

- Even if your pipes haven’t failed yet, they often do within a 10-15 year time period, so it is likely that they will fail soon.

Sources

https://www.acplasticsinc.com/informationcenter/r/types-of-plastic-pipes-for-plumbing

https://www.fallonsolutions.com.au/plumbing/information/the-dangers-of-flexi-hoses

https://resources.saylor.org/wwwresources/archived/site/wp-content/uploads/2011/07/ME303-4.1.1.pdf