A seized anode rod is not uncommon. It is primed for reactivity and corrosion in the water heater. Thankfully, you can use one or more of these 9 tips for removing the seized rod. These tips range from using what’s on hand, to specialized tools, to preventative measures. Hopefully, I can save you time, energy, pulled muscles, and future difficulties!

- Ensure water heater is off and partially drained

- Secure the water heater

- Try a pipe wrench

- Use liquid wrench

- Use breaker bars

- Use cheater bars

- Try tightening the rod first

- Use impact wrench

- Use Teflon tape for the new anode rod

1. Ensure Water Heater Is off and Partially Drained.

You need to turn off the electricity (at the circuit breaker) or gas (set it to vacation mode to prevent the pilot from igniting) to the heater, as well as close the cold-water supply.

This is important because you would be dealing with water and electricity, potential gas emissions, or an appliance that can heat and burn you if they are not correctly off.

Once you have shut off the electricity/gas and then the water, you need to drain the heater using the drain valve at the bottom. You only need to drain some of the water while leaving the temperature and pressure relief (TPR) valve covered.

To drain the water, you can attach a garden hose to the drain valve connection and siphon some water out the tank and into a bucket or even a bathtub. Of course, you’ll need a bucket big enough to hold the amount of water being extracted!

Once that is set up, you can open the pressure relief valve at the top of the heater. Be mindful of the hot water! It shouldn’t take long to drain a little water, and then just close the pressure relief valve to stop the flow.

2. Secure Your Water Heater

It is essential to have the water heater secured before removing the anode rod. If you are tugging at the seized rod and the heater keeps moving, your efforts will be wasted.

If you live in an area with a Seismic Design Category (SDC) that requires seismic strapping (which will be double strapping), your water heater is already braced against movement. It is designed to hold the weight of the heater along with significant force acting on that heater.

If you do not have seismic strapping, you will need someone to hold the tank still, or you will need to try and create a strapping system of cables as best suits your situation.

Straps might still be helpful as a grip for someone holding the tank. By providing good handholds, they can brace better against the force you exert. You can also always call in more than one assistant to brace the heater from multiple sides.

Cables, ropes, or chains (be careful not to damage your tank) can secure the tank. Strapping your heater in the top and bottom thirds of the heater will be the most secure method.

You can attach the straps to suitable anchors around the heater, or you might need to drill brackets into the walls. It would be worthwhile installing these brackets because anode rods need to be replaced regularly.

Having most of the water in the tank also helps hold the heater in place by adding weight to it. If you have drained too much water, you will likely have trouble with the heater shifting.

The video below shows a clever rigging and bracing system created using a ratchet strap and some wood.

3. Try a Pipe Wrench if Rod Is Not Recessed

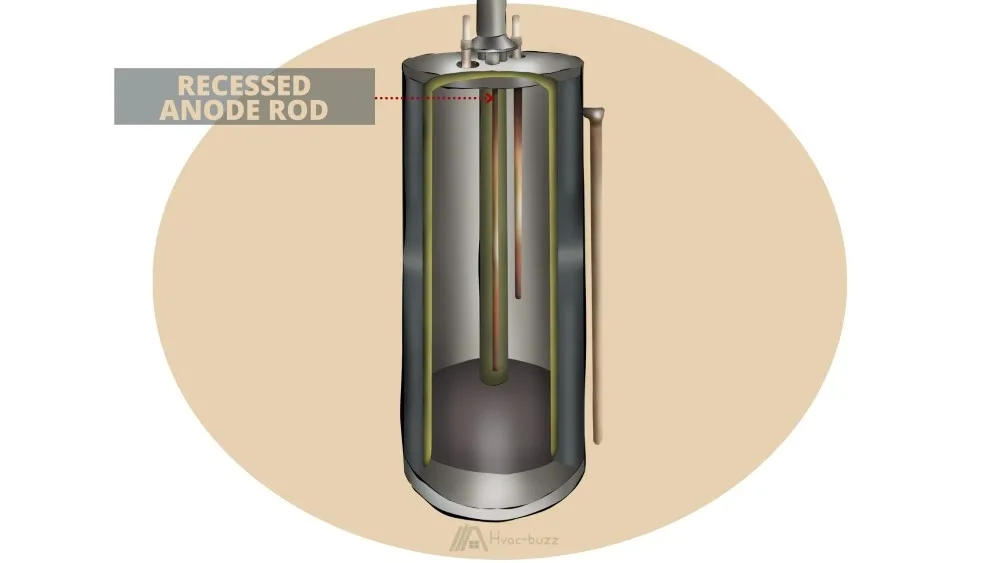

If the anode rod insert point is not recessed (or sunk) into the water heater, you can try using a pipe wrench to remove it.

If the rod is recessed, the large and bulky head of a pipe wrench will not grip the fastener properly. Pipe wrenches need to attach straight, and the recessed anode rod will not be level enough with the water tank to allow this, meaning that you cannot get the necessary positioning and leverage to loosen the rod.

Now, anode rods are not typically recessed into the water heater because of the issues it causes with replacement, but you might have an odd model, or the tank might be bent from previous wrestling with a seized anode rod.

If your anode rod is not recessed and there is enough workspace for a pipe wrench, this is a pretty easy solution to try. The pipe wrench might be able to offer you the force needed to unstick the threads.

Attach the wrench to the fastener and tighten the nut to secure the wrench in place. It should be positioned so that the opening of the jaw is facing the way you are trying to twist the fastener.

4. Use Liquid Wrench

Liquid wrench is a lubricating oil spray designed to break down rust. If your anode rod is fused in place, spraying some of this onto the connection and allowing it to sit a while will help dissolve the rust jamming the threads.

Using a wire brush on the connection before applying the product will help with penetration into the threads.

While you may not be able to unscrew the rod by hand after using the product, this could mean that your regular old wrench will do the job.

You should follow the manufacturer’s directions to get the best results once you have acquired the appropriate liquid wrench product, such as the Liquid Wrench Lubricating Oil (amazon link).

It’s worth noting that when you use a lubricant, you may end up with some of the product getting in the tank and remaining water. If you would prefer to avoid that outcome, you can try some of the other options.

5. Breaker Bars Increase Leverage

A breaker bar is a metal rod with a socket head that can rotate 240° to provide optimal leverage. This allows you to get the force needed to remove the rod without having to strain physically.

Length is key with breaker bars: the longer the bar, the more torque it produces. In a range of 18” (likely too small to fit) to 40”, a breaker bar around 30”, like the Capri Tools 30” Breaker Bar (amazon link), is a good choice for a heavily rusted anode rod, but you can consult a professional if you are unsure.

You need to attach the socket to the head of the anode rod and work it loose. Yes, the longer bars produce more force, but you still need to be able to get the breaker bar into the space around the anode rod and wield it properly.

A 40” bar can be harsh and damaging. If a 40” bar cannot loosen the anode rod, you are going to have to cut it off, and I recommend calling a plumber.

6. Further Increase Leverage With a Cheater Bar

Cheater bars work on the same principle as breaker bars: add extra length to increase the leverage so that you don’t have to strain.

Cheater bars attach to a breaker bar or any wrench you are using, provided they can fit over the handle without going too far down to make them useful.

A bonus here is that there are some fantastic DIY options. The easiest thing to use for your breaker bar would be to cut the desired length of stiff garden hose or a piece of piping. An 18″ piece of steel pipe or rigid hose should do the job, but you can choose a length best suited to your needs.

Be careful about how much length you add as you don’t want to damage your water heater.

7. Try Tightening the Rod First

As counter-intuitive as this may seem, anode rods are designed to screw in more than screw out. So, you can get the connection to budge by going in the direction that is more likely to provide movement.

Once you break that initial seal and achieve some motion on the threads, you will likely find that you can make progress on unscrewing the rod.

This is a process of tightening and then loosening on repeat until you get the rod out. You can also add some lubricant into the mix to try and speed up the process.

8. Impact Wrenches Are Very Successful

Thankfully, there is also a powered option for loosening an anode rod, which will require less energy from you. Impact wrenches are a power tool that adds vibration to the bolt head of the anode rod to provide jarring movement to help loosen the rusted threads.

Impact wrenches have a head that is designed to fit over hex-shaped fasteners—the kind you will find on an anode rod. It provides a hammering movement at low speed that creates a burst-like twisting motion that is exceptionally helpful for loosening your seized anode rod.

These wrenches come corded (PORTER-CABLE Impact Wrench (amazon link)) or cordless (DEWALT Cordless Impact Wrench Kit (amazon link)), can be air- (pneumonic) or battery-powered, and there are adapters available to help you fit the tool to your anode rod.

- 1/2 inch cordless impact wrench has up to 700 ft-lbs of max torque and 1200 ft-lbs of max breakaway torque

- DEWALT 1/2 inch impact wrench has a compact design of 8-13/16-inch in length

- Multi-speed control of the battery-powered impact wrench is made for a variety of applications (0-400/ 1,200/ 1,900 RPM)

- 1/2-inch Anvil with detent pin (also available with hog ring)

- Performance: Delivers a max. torque of 600 ft.-lbs. and offers enough power to install and remove stubborn bolts, lug nuts, and other hardy fasteners.

- Reliable Choice: Lightweight and easy to maintain, this impact wrench is a reliable choice for auto hobbyists and professional mechanics alike. Built to withstand harsh environments and repeated...

- Adjustable Power: Its adjustable power regulator lets you easily adjust power output needed for your task at hand; The twin hammer mechanism helps ensure efficient performance with impressive...

- Comfort and Control: At 7.3 inches in length and weighing only 5.8 lbs, it's compact, ergonomic design minimizes stress on your wrists and hands; The contoured handle makes it easy to carry and...

Last update on 2024-03-27 / Affiliate links / Images from Amazon Product Advertising API

If you are looking for more information check out Can Anode Rod Be Removed With an Impact Wrench.

9. Use Teflon Tape on New Anode Rod

Teflon cannot help you once your anode rod is seized, but it can help you prevent the seizing from happening if you use it when installing the next rod.

Teflon is the original brand name for polytetrafluoroethylene (PFTE), which is a non-stick coating. Due to strong carbon-fluorine bonds in the substance, it is highly unreactive and is excellent to use with an anode rod.

When it comes to plumbing, Teflon is used to create better sealing between parts and has a high temperature tolerance.

Using the tape between the threads on the anode rod and the threads on your water heater will not compromise how secure your anode rod is.

Another benefit is that it acts as a layer of lubricating material between the metal parts that will prevent rust from fusing them together and prevent the corroded rod from seizing.

Teflon tape comes in a range of widths, so you need to ensure the tape is appropriate for your anode rod (although it is very stretchy).

A 1/2” width, like Vomtell Teflon Tape (amazon link), is very versatile and might serve you best if you are unsure about what to buy. Wrap it around the anode rod threads and fasten it into place.

Sources

https://www.jupiterheating.com/bock-water-heaters/bock-help-remove-anode-rods.html

https://www.callks.com/blog/how-to-drain-a-water-heater/

https://www.plumbingsupply.com/how-to-change-a-water-heater-anode.html

https://homeguides.sfgate.com/how-to-use-liquid-wrench-13415115.html

https://www.bobvila.com/articles/best-breaker-bar/

https://www.protoolreviews.com/impact-driver-vs-impact-wrench/

https://www.sgs-engineering.com/help-advice/what-are-impact-wrenches-and-impact-drivers/

https://www.techbelt.com/what-is-teflon-tapes/

https://www.hillsirrigation.com.au/when-not-to-use-teflon-tape-4-times-to-think-before-you-wrap/

https://www.familyhandyman.com/article/pipe-wrench/