When it comes to insulating our homes, we often focus on factors like fireproofing and waterproofing. But one aspect is often overlooked: sun protection. The sun’s ultraviolet (UV) rays can break down certain materials in thermal insulation over time, leading to physical damage and reduced performance.

When exposed to sunlight, insulation can suffer from various types of damage, including discoloration, warping, cracking, and ultimately loss of insulating properties. The damage sunlight will have on your home’s insulation will depend on the insulation you have installed and how long it is exposed for.

Sunlight damages insulation in different ways. Plastic foam insulation will degrade the quickest, then fiberglass. Natural insulation can last up to a few years in direct sunlight but will eventually degrade. Mineral wool insulation will not be damaged by sunlight.

Fiberglass Insulation

You may think that sunlight won’t affect fiberglass insulation because it is made up of tiny pieces of glass, and glass is readily exposed to sunlight in many other areas of life.

However, sunlight can significantly affect fiberglass insulation, particularly if it is exposed to direct sunlight for prolonged periods.

Fiberglass insulation is held together by resin. When the insulation is exposed to sunlight, the UV rays can cause the resin to break down and deteriorate over time. The insulation becomes brittle and is less effective at trapping air and insulating your home.

It’s important to ensure your insulation is installed properly and covered with something like drywall or a vapor barrier. That way, it won’t be exposed to direct sunlight for too long and can do its job efficiently.

UV rays can take up to a few years to damage your fiberglass insulation. It all depends on a few factors, like the quality of the insulation resin, how thick the insulation is, and how much direct sunlight it’s exposed to.

If you need to dry out your insulation, say, after a flood, leaving the insulation out to dry in the sun for a few hours won’t do any harm.

However, if you have a window in your attic where the sun shines onto your insulation all day, you may want to consider covering that section up.

Natural Insulation

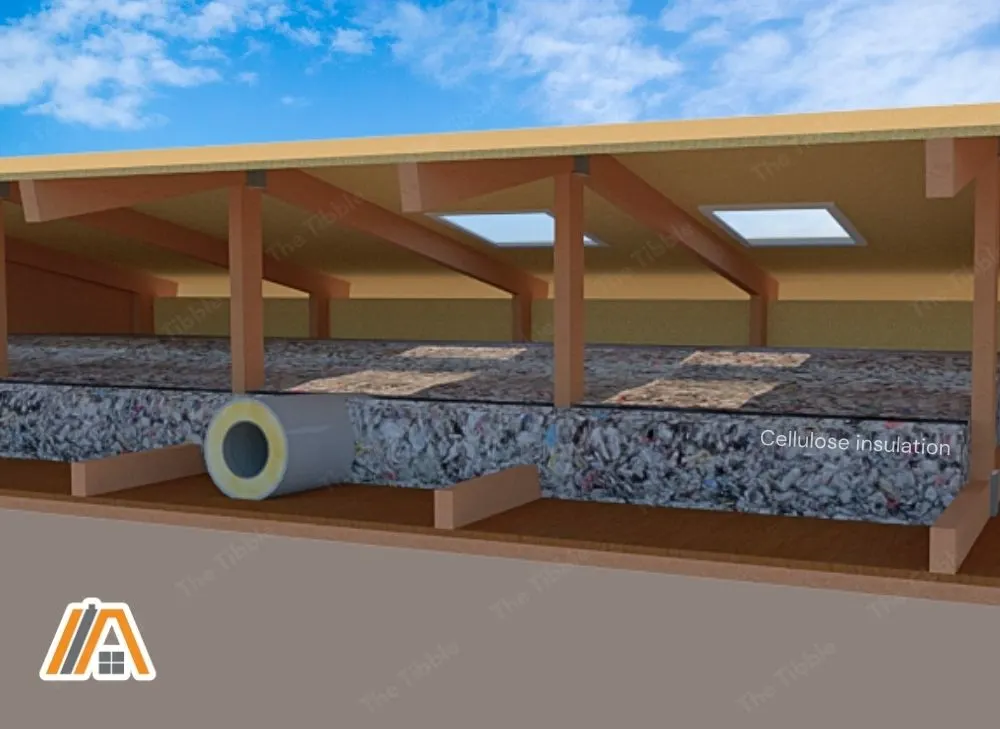

Cellulose

Cellulose insulation is made from recycled paper products, like old newspapers or cardboard, which makes it a great sustainable option. However, when cellulose insulation is exposed to sunlight, the UV radiation in the sunlight can cause it to degrade over time.

Just like when we leave old newspapers outside, they get thin, crinkly, and change color. This process is because the UV radiation from the sun breaks down the chemical bonds in the fibers that make up the cellulose, which can weaken and discolor the insulation.

The insulation becomes brittle, and its ability to maintain its insulating properties decreases. As the cellulose insulation degrades, it can also begin to settle and compact, reducing its thickness and further reducing its insulating properties.

If your cellulose insulation gets wet and you need to dry it out, it can be left out in the sun for a few hours, but anything more, and it will start to fade. Leaving your cellulose insulation in direct sunlight after a few days will cause it to degrade.

It is best to cover up your cellulose insulation in the areas constantly exposed to the sun, such as comes through windows in the attic.

Hemp

Hemp insulation is made from the fibers of the hemp plant; it is non-toxic, biodegradable, and energy-efficient, resistant to fire, pests, and mold, and has excellent thermal and acoustic insulation properties. Not only that, hemp is known for its high resistance to ultraviolet (UV) light.

Hemp insulation contains natural pigments and compounds that protect it from the sun’s harmful rays. Hemp fibers contain a substance called lignin, which is a complex organic polymer that gives the plant its structural support.

Lignin is a natural sunscreen and has been shown to provide effective protection against UV radiation. So, not only is it a great insulator, but it can also withstand the harsh sun without degrading over time.

In addition to lignin, hemp fibers contain other pigments, such as chlorophyll, which also provide some UV protection. The combination of these natural compounds makes hemp a highly UV-resistant material, which is especially important for insulation that is exposed to sunlight.

This means that in such situations, hemp insulation can maintain its insulating properties and effectiveness for a longer period of time than other types of insulation that are more susceptible to UV damage.

Cork

Cork insulation has some level of UV resistance due to the natural properties of cork. Cork comprises a waxy substance called suberin, which acts as a natural protector against environmental stressors, including UV radiation.

Cork insulation is more resistant to sunlight damage than other insulation types. However, this natural resistance may not be enough to fully protect the insulation over a long period of time, especially in areas with high levels of sun exposure.

Exposure to the sun for long periods of time will also cause the cork to fade. Many people who have installed cork floors in their homes have noticed this trend. If not coated with a UV protective layer, the cork will also break down and become brittle.

Cork, in itself, is already dry. When it is exposed to sunlight for long periods of time, it can dry out completely and become very crumbly. Think of opening an old wine bottle. If the cork doesn’t stay moist, it usually disintegrates with the action of the corkscrew.

However, cork won’t dry out overnight. You’ll have a few years before the damage really starts to set in. So, if your cork insulation is exposed to the sun, make sure it is treated with a good UV protection layer. This will ensure it lasts much longer.

Wool

Wool insulation is made from the natural fibers of sheep wool, making it a renewable and sustainable insulation option. One of the unique features of wool insulation is its UV resistance.

Wool contains a natural pigment called melanin, the same pigment we have in our skin. Melanin plays a crucial role in protecting tissues from the harmful effects of UV radiation. By absorbing the UV rays from the sun, melanin acts as a natural sunscreen.

Studies on the UV resistance of wool have shown it to have a protection rating of up to SPF 30+, which means it provides significant protection against the sun’s harmful rays.

Wool insulation’s natural UV resistance means it can withstand prolonged exposure to sunlight without degrading or losing its insulating properties.

Wood Fiber

Wood fiber insulation is another great option for those looking for an eco-friendly and sustainable insulation choice. It is made from wood chips or sawmill shavings that are processed into a fibrous material, making it a renewable resource.

Like hemp, wood fiber insulation contains lignin, a natural polymer that provides some level of UV protection. Although it is considered to possess natural UV-resistant properties, it is not as effective as cork insulation.

Like many materials, prolonged exposure to the sun can cause it to break down and lose its effectiveness. This can happen due to the breakdown of chemical bonds in the wood fibers, causing the insulation to become brittle and weak.

Additionally, the insulation may start to fade and lose its color over time due to the effects of UV radiation. While it may not be as resistant to sunlight damage as cork insulation, proper care and maintenance can help extend its lifespan.

Cotton

Cotton insulation is made from recycled denim and other cotton products, making it an eco-friendly and sustainable option for insulation. But how does cotton insulation compare to other natural materials, like hemp?

When it comes to UV resistance, cotton insulation is most similar to hemp insulation. The lignin in cotton fibers provides some UV protection, but not as much as hemp. Hemp fibers contain more lignin, giving hemp better UV resistance than cotton insulation.

That being said, a study on cotton fabrics showed that it took eight months of exposure to sunlight for signs of degradation and weakening to appear. The rate of damage to cotton insulation by sunlight depends on the intensity and duration of exposure.

So, again it is safe to leave your cotton insulation out in the sun for a few days, maybe even a few weeks. But longer than a few months, and you may find yourself needing to replace it.

Straw

Straw insulation is a popular choice for eco-conscious builders because it is a renewable resource that can be obtained relatively cheaply. It is made from tightly compressed straw bales, a byproduct of wheat, rye, and barley production.

Straw insulation has no natural UV resistance like wool or cork insulation. Having said that, people have been using straw bales in house construction and outdoor furniture and decor for over a century.

However, as with other natural insulation options, exposure to sunlight over a couple of years may cause the straw insulation to lose its insulating properties over time. Long-term exposure to sunlight may cause the straw fibers to weaken and become brittle and may also cause the insulation to fade and discolor.

While straw insulation is a good option for eco-conscious builders, it is important to consider the material’s fire resistance. Straw bales are typically treated with a fire retardant solution to make them fire-resistant, but the sun can break down these chemicals over time.

Without a proper fire-resistant coating, straw bales can be extremely flammable and pose a serious fire hazard. Covering or shading any sections of your straw insulation from the sun is best. This will ensure your insulation lasts longer and is a safe and efficient insulator.

Mineral Wool

Mineral wool insulation is made from natural and recycled materials, specifically basalt rock and recycled slag. One of the great things about mineral wool is it is made from natural stone or slag (a byproduct of steel manufacturing), making it an inorganic material.

Inorganic materials are those that do not contain and are not derived from living organisms. Examples of other inorganic materials include minerals, metals, ceramics, glasses, and some polymers.

Since inorganic materials do not contain any organic matter, they are not subject to decay or degradation from exposure to sunlight, moisture, or microorganisms, making them highly durable and long-lasting.

Mineral wool, therefore, does not contain any organic materials that could be subject to degradation from exposure to sunlight. This makes mineral wool insulation an excellent choice for applications where long-term exposure to sunlight is expected.

While exposure to sunlight may cause some discoloration of the insulation, this should not affect its overall performance as an insulator. The durability of mineral wool insulation also means that it can provide long-lasting thermal insulation for many years without significant loss of performance.

Plastic Foam Insulation

Spray Foam

Spray foam is an effective insulation option for homes and buildings, but it has a major weakness when it comes to exposure to ultraviolet rays from the sun. Sunlight can cause damage to spray foam insulation through a process known as photodegradation.

Ultraviolet (UV) radiation from the sun breaks down the chemical bonds in the foam, causing it to become hard and flakey. Without proper protection, spray foam will begin to deteriorate within 72 hours of being exposed to sunlight.

In fact, under direct sunlight, spray foam can degrade at a rate of 1/16th inch per year. This means that if the foam is not protected, it can quickly lose its insulating properties and structural integrity, potentially leading to significant problems for your home.

It is important to cover spray foam insulation with a protective layer to protect it from UV damage. One option is to use a UV-rated paint specifically designed to shield the foam from the sun’s destructive rays.

It is recommended that the coating be applied the same day the foam is sprayed to ensure maximum protection. Even a delay of one day can be enough for the UV rays to start degrading the foam.

Rigid Foam Board

Rigid foam board insulation is made up of a rigid foam core, typically composed of polystyrene or polyurethane, and is covered with a facing material that can be made of paper, foil, or other materials.

Like spray foam insulation, foam board insulation can also be susceptible to damage from the sun’s UV rays.

Over time, the sun’s UV radiation can cause the foam to break down, leading to a loss in its insulating properties. If left exposed to the sun for more than 60 days, the foam board insulation can begin to warp and deteriorate.

Some foam board products come equipped with a protective laminate surface on both sides to mitigate the effects of UV radiation. This protective layer can help to resist UV damage for a longer period of time.

However, it is still important to cover any exposed foam board insulation exposed to sunlight within 30-60 days at most to ensure its longevity.

In addition plastic foam insulation is considered a fire risk when it is not covered by a thermal barrier. So, if sunlight can reach your plastic foam insulation, it is not installed as per code requirements.

Sources

https://westcalinsulation.com/what-is-uv-stability/

https://www.sciencedirect.com/science/article/pii/S0926669021009778

https://pubs.rsc.org/en/content/articlelanding/2015/gc/c4gc01333f

https://www.archives.gov/publications/prologue/2016/spring/preserve-clippings.html

https://wamaunderwear.com/blogs/news/hemp-clothing-sun-protection

https://www.homelogic.co.uk/disadvantages-of-cork-flooring-for-homes

https://corksoluk.com/latest-news/how-long-does-cork-last/

https://www.americanwool.org/wool-101/science-of-wool/

https://www.homebuilding.co.uk/advice/wood-fibre-insulation

https://4spepublications.onlinelibrary.wiley.com/doi/abs/10.1002/pc.20048

www.internationalscholarsjournals.com/articles/effects-of-uv-irradiation-on-plants.pdf

https://www.bobvila.com/articles/straw-bale-diy/

https://designwithfrank.com/blogs/building-guide/how-straw-bales-can-be-used-for-insulation

https://wentzelheatingandair.com/insulation/spray-foam/faq/

https://westroofingsystems.com/weakness-spray-polyurethane-foam-roof/

https://www.goodguyssigns.com/blog/foam-board-pros-and-cons/