Vapor barrier is needed for Rockwool insulation if the geographic location requires it. Generally places that get cold winters require vapor barriers.

What Is the Purpose of an Insulation Vapor Barrier?

Common insulation types, like cellulose, fiberglass, and rockwool work by trapping air in small pockets, which helps to slow down the transfer of heat between the inside and outside of a building.

It does this in two ways:

- It traps warm air, preventing it from passing through the insulation.

- Air is a poor conductor of heat, so the trapped air also does not allow the conductive transfer of heat.

When insulation gets wet, the spaces are filled with water. While air cannot pass through the water very easily, heat can. Water is a notoriously good conductor of heat. This means that the insulation won’t work as well to keep the building warm or cool.

The purpose of the vapor barrier is to prevent moisture that is generated inside the building from migrating into the insulation and causing it to become damp.

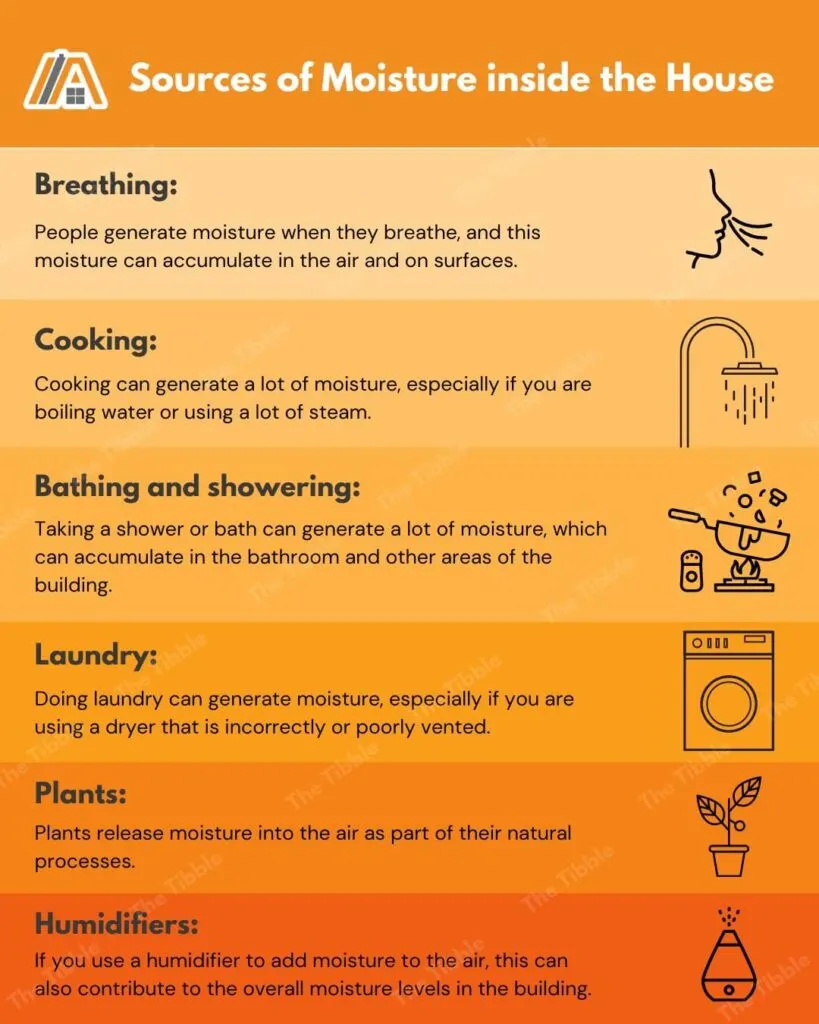

These sources of moisture include:

- Breathing: People generate moisture when they breathe, and this moisture can accumulate in the air and on surfaces.

- Cooking: Cooking can generate a lot of moisture, especially if you are boiling water or using a lot of steam.

- Bathing and showering: Taking a shower or bath can generate a lot of moisture, which can accumulate in the bathroom and other areas of the building.

- Laundry: Doing laundry can generate moisture, especially if you are using a dryer that is incorrectly or poorly vented.

- Plants: Plants release moisture into the air as part of their natural processes.

- Humidifiers: If you use a humidifier to add moisture to the air, this can also contribute to the overall moisture levels in the building.

The vapor barrier is installed on the warm side of the insulation (the side that faces the interior of the house).

The structural beams between and/or over which the insulation is installed also benefit from the vapor barrier.

Even though the wood-framing is treated or naturally moisture-resistant, eventually moisture exposure can start to penetrate the wood, which rots and may collapse.

While this does not protect the beams from all possible sources of moisture, it does protect them from a few, which is important.

Rockwool Is Moisture-Resistant and Vapor-Permeable

Rockwool insulation is actually made from natural stone or recycled slag and not wool. It is both moisture-resistant and vapor-permeable.

While this seems paradoxical, it all comes down to the form of water.

Liquid water cannot be absorbed by rockwool. Water vapor, on the other hand, can move through the material to a certain extent.

Rockwool is resistant to liquid moisture because the fibers that make up the material are hydrophobic, which means that they repel water. This makes it difficult for liquid water to penetrate the insulation and cause damage.

The vapor-permeability of rockwool is due to the fact that the gaseous water molecules are further apart from each and can, therefore, squeeze between the fibers without being as affected by their hydrophobic nature.

When it comes to protecting insulation from moisture-related damage, if there is a possibility that water can get in, then the best defence is its ability to get out again. So, the vapor-permeability means that vapor will pass through the rockwool instead of getting trapped within.

Does It Depend on the Level of Moisture?

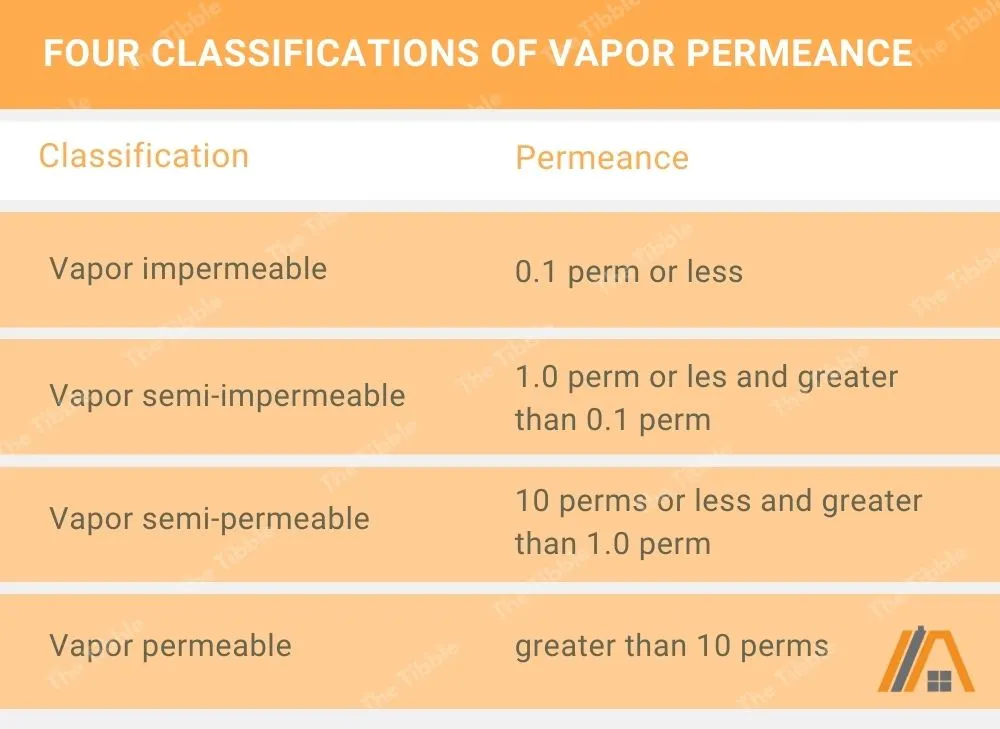

While rockwool insulation is described as vapor-permeable, this is actually a relative term. It is permeable compared to other completely impermeable materials. However, its perm rating actually classifies it as a Class II vapor retarder.

This means that rockwool is not completely impermeable to water vapor, but it still provides a significant barrier that helps to prevent moisture from accumulating in the insulation or other parts of the building envelope.

Being a Class II vapor retarder, it is considered less effective than something like plastic sheeting, which is a Class I vapor retarder, but more effective than options like enamel paint, which is a Class III vapor retarder.

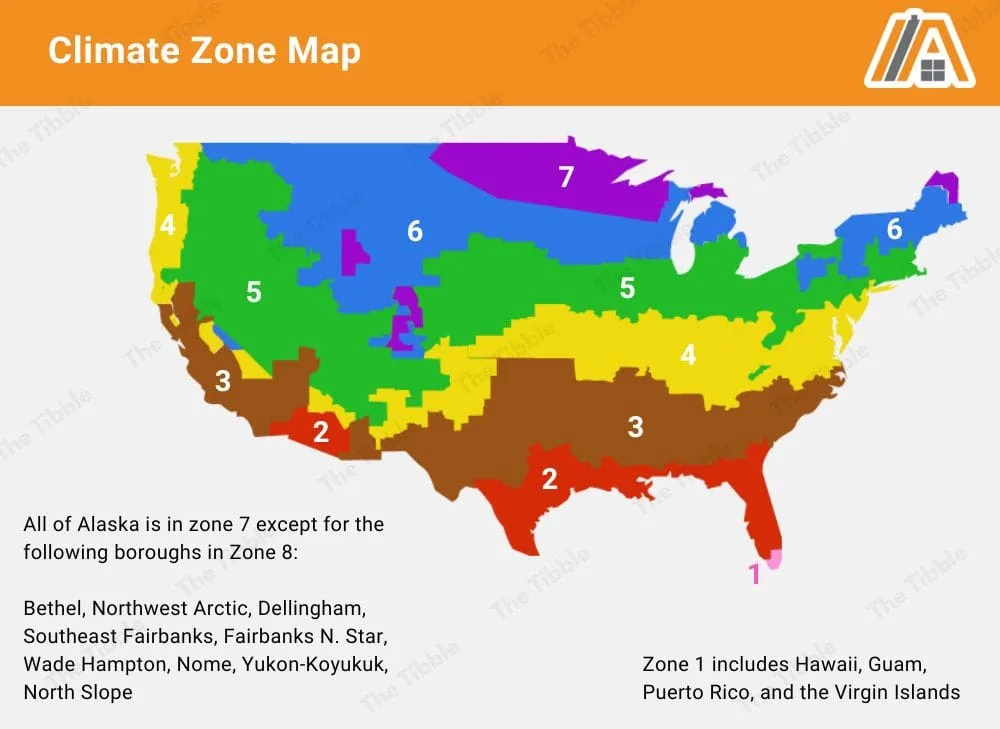

This is pertinent because there are some climate zones that do not consider Class II vapor retarders as sufficient protection.

According to Table R702.7 of the International Residential Code, Class II vapor retarders, like rockwool, are not permitted in climate zones one and two. These climate zones are described as extremely hot and humid and very hot and humid.

Humidity means there is more water vapor in the air that the vapor retarder has to “fight” against. There are other climate zones that are humid, but the combination with heat is what makes it more problematic.

A cold climate cannot reach the same humidity levels as a hot climate because cold air cannot hold as much moisture as hot air. This means that the moisture levels in conjunction with the average temperature of an area can make rockwool an insufficient vapor barrier.

Some Come With Foil Facing

Rockwool insulation sometimes comes with a foil facing. The foil facing is a thin layer of reflective material, typically made of aluminum, which is designed to protect the rockwool insulation from moisture and air.

The facing is attached to one side of the rockwool insulation and serves a number of functions:

- The metal surface helps to prevent radiant heat transfer, which rockwool itself cannot do.

- It prevents condensation from forming on the surface of the insulation. Even if the water cannot be absorbed, it can sit on the rockwool and provide an opportunity for mold growth.

- It acts as a support in moisture protection.

While it provides additional protection against moisture and nonperforated aluminum foil is a Class I vapor retarder by the IRC, the the foil facing is not enough to elevate rockwool to Class I.

The foil facing is not a continuous barrier. The insulation, and thus, the batts, are installed in strips separated by joists or studs. The gaps are also enhanced through incorrect measuring and improper installation.

This means that vapor can bypass the barrier, making it fallible.

Installing a Vapor Barrier

Rockwool insulation in itself is a good vapor barrier, so if you are needing a Class II or III vapor barrier, the rockwool insulation will be sufficient.

However, in areas with consistent exposure to high levels of moisture or extreme humidity for most months of the year, a Class I vapor barrier may be required. In fact the IRC Code R702.7 states that if you live in Climate zone 5, 6, 7, 8 and marine 4 you need to have either a Class I or Class II vapor retarder.

Class I vapor barriers have a perm rating of less than or equal to 0.1 and provide a more robust moisture barrier to protect the insulation and your home. These are considered to be vapor impermeable.

Some options for Class I vapor retarders are polyethylene sheeting and non-perforated aluminum foil.

The vapor barrier should be installed on the inside of the insulation because most of the moisture is going to come from the inside your home, where the temperature is warmer. This helps to prevent the moisture from penetrating the insulation and getting into your walls from the inside.

Sources

https://www.homedit.com/rockwool-insulation/

https://www.rockwool.com/north-america/advice-and-inspiration/

https://www.attainablehome.com/ultimate-vapor-barrier-guide-faq-answered/

https://www.attainablehome.com/when-do-you-need-a-vapor-barrier/