Perhaps you are concerned about the building code regulations, or you need to replace a duct line and have some 4” ducting lying around. Whatever the reason, there are some things to consider when adjusting your duct size.

All exhaust fans, whether it’s your bathroom fan, range hood, or dryer, work with a pressure system to remove air (and anything else) from your home. Understanding how this pressure works and is affected by your ducting can help you see if you will cause issues by reducing its diameter.

Exhaust ducts have an optimal size, which can be found in the building code and manufacturer recommendations. Smaller ducts result in more duct pressure. This slows airflow, creates more noise, and increases energy consumption.

What Duct Size Is Fan Designed For?

The drawbacks depend on if you are reducing the duct size below the recommended diameter.

If the exhaust system were designed to work with either a 6″ or a 4″ duct (it would have come with an adjustable connection point), then the effects of changing from the 6″ to the 4″ would be minor or negligible.

If, however, the system was designed for a 6″ duct and you installed an adapter that allows you to attach a 4″ duct, then you are likely to experience the following drawback in a significant way.

Smaller Ducts Mean Impaired Airflow

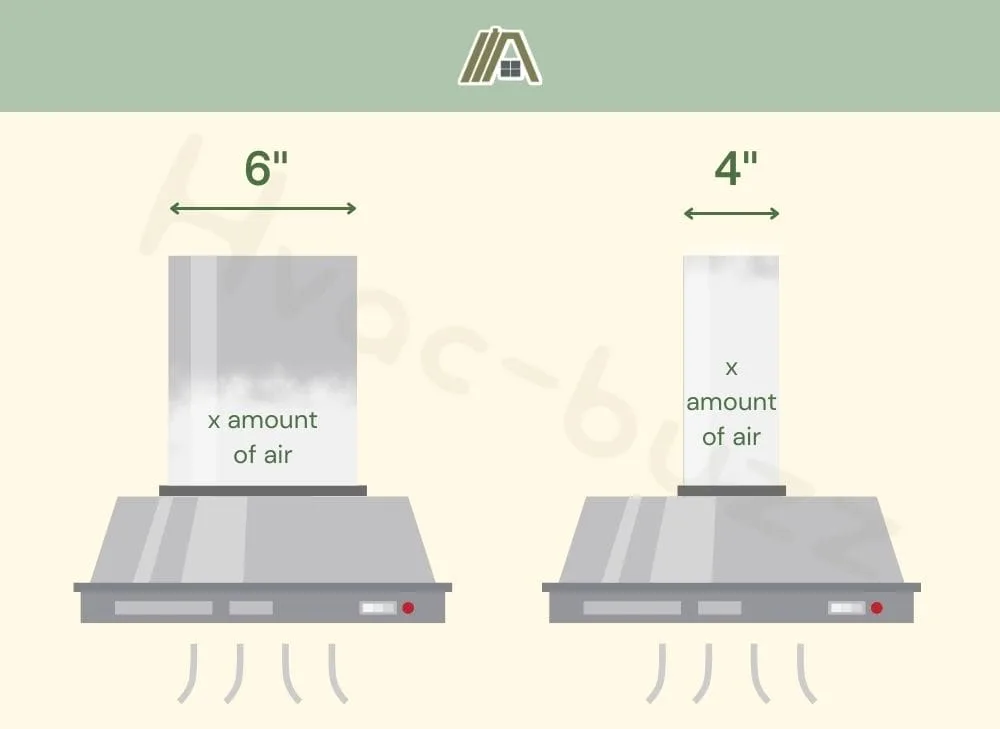

If your exhaust system is meant to run with a 6″ duct and you attach a 4″ duct, then you slow the air down by increasing the pressure in the duct.

While you might think that increased pressure means the air would flow faster, it’s actually a bit more complicated than that.

There are actually two types of pressure exerted by the air traveling through an exhaust duct.

The first is velocity pressure, which provides forward momentum to the air. If this were the only type of pressure in the system, then, yes, the smaller duct would mean a greater rate of airflow and, therefore, a greater exhaust rate.

However, there is another pressure called static pressure. This is the force exerted by the air against the duct itself. As the air presses against the duct, it loses some of its energy.

It might make more sense if you consider static pressure’s alternative names: friction or resistance. This increases when more of the air in the duct is in contact with its surface at one time.

In a narrower duct, x amount of air is spread out over a greater length of the duct, increasing the amount of air in contact with the duct.

When an exhaust system is designed, the duct size is chosen based on what diameter will yield the best balance between velocity and static pressure.

By reducing the duct size, you increase both the velocity and the static pressure. To achieve the same result, the fan’s motor will have to work harder, but the fans are only designed to work at a certain capacity, so it is very difficult for the motor to keep up with the increased requirements.

The end result is that the air is slowed down.

Consequences of Slowing Airflow

Bathroom Fan

Bathroom exhaust fans remove heat and humidity to prevent steam build-up, condensation, and moisture damage. The fan’s ducting is the most common cause and solution to bathroom condensation.

It’s no different when it comes to a pressure issue related to duct size. The slower the steamy air moves through the exhaust vent, the more time it has to cool while still in the duct. When this happens, water condenses out of the air, runs through the ducts, and causes dripping from the fan.

You need to consider what size duct is best for you by looking at the situation of your bathroom and exhaust system.

Range Hood

You are capping the function and efficiency of your range hood by using an incorrectly sized duct.

No matter the setting, there will be a limited amount of air the system can exhaust at a time.

Since a range hood removes heat, moisture, grease, and odors associated with cooking, you will not benefit properly.

Your kitchen will quickly get hot, smokey, and smelly. Not to mention the extra grease you will have to scrub from the walls, stove, and cupboards.

Dryer Exhaust

A dryer vent exhausts the heat generated by the appliance and the moisture and lint it removes from your clothing.

If airflow is slowed by a small duct, you will encounter problems with condensation, causing dripping, and damage associated with water.

Lint can also build in the ducting, which is a fire hazard especially combined with heat from the dryer. This is part of why the International Residential Code provides specific regulations for dryer vents and their duct dimensions.

This smaller ducting also makes the dryer work harder to exhaust byproducts, which impacts its lifespan.

Reduced Duct Size Means More Noise

What I did not explain about static pressure in the previous section is that the energy losses associated with it are the result of the air molecules colliding with the duct walls. As a result, energy is transferred from the air molecules to the duct, leaving less energy with which the air can move forward.

Now, these collisions also create turbulence, and the air molecules change trajectory after contact with the duct wall. The more molecules in contact with the duct wall (as when the ducts are smaller), the more molecules are redirected in all different directions.

The balance between laminar flow (straight flow) and turbulent flow is upset in favor of turbulence (for that system). But how does that increase the noise?

Well, the energy transferred to the duct is kinetic (the energy of movement). So, the ducts will vibrate and rattle in response to turbulent airflow within the ducts. And because they are hollow passageways, this noise is carried very well throughout the house.

Power Consumption Increases With Reduced Duct Size

As mentioned previously, the fan must work much harder to move air through a smaller duct.

Since the pressure from the smaller space almost pushes back, the fan must do more to overcome this pressure build-up. This requires more power, which means that your fan draws more electricity.

The harder it works, and the more electricity that flows through the fan’s motor, the more likely it is to wear down, and the faster this will happen.

It will also be more prone to overheating, which has its own risks for appliance damage and fires.

Would Increasing Duct Size Be Beneficial?

There is a sweet spot when it comes to duct size, meaning there is a limit to “bigger is better”.

For example, when you have a longer duct (which increases resistance), you can size up from a 4″ to a 6″ duct. This can improve exhaust efficiency by decreasing resistance.

However, there is no point in going beyond a 6″ diameter. This is because increasing the duct size decreases both static and velocity pressure. So, yes, you would have less resistance in the duct, but you will also get less forward momentum.

Therefore, you can make your fan ineffective with inappropriate ducting. Of course, this is only true if the fan is not powerful enough to force the air all the way through the ducts. If it is powerful enough, then the air movement is active, not passive.

Sources

https://homeinspectioninsider.com/size-dryer-vent/

https://www.energyvanguard.com/blog/The-2-Primary-Causes-of-Reduced-Air-Flow-in-Ducts

https://www.donmarcompany.com/about-us/blog/2018/august/four-common-problems-with-your-ductwork/

https://www.theseverngroup.com/your-duct-size-does-matter-and-material-too-in-commercial-hvac/

https://vicsairconditioning.com/blog/the-importance-of-proper-duct-sizing