R50 insulation is not the most commonly used rating for insulation. Even so, with the various options and choices that can be made regarding insulation, knowing about R50 is a helpful piece of knowledge to have.

This article will discuss not only R50 but also R49 and the differences between the two, and why R49 tends to be more common. Most importantly, though, in this article, you will find a straightforward and easy-to-read table for R49 and R50 thicknesses.

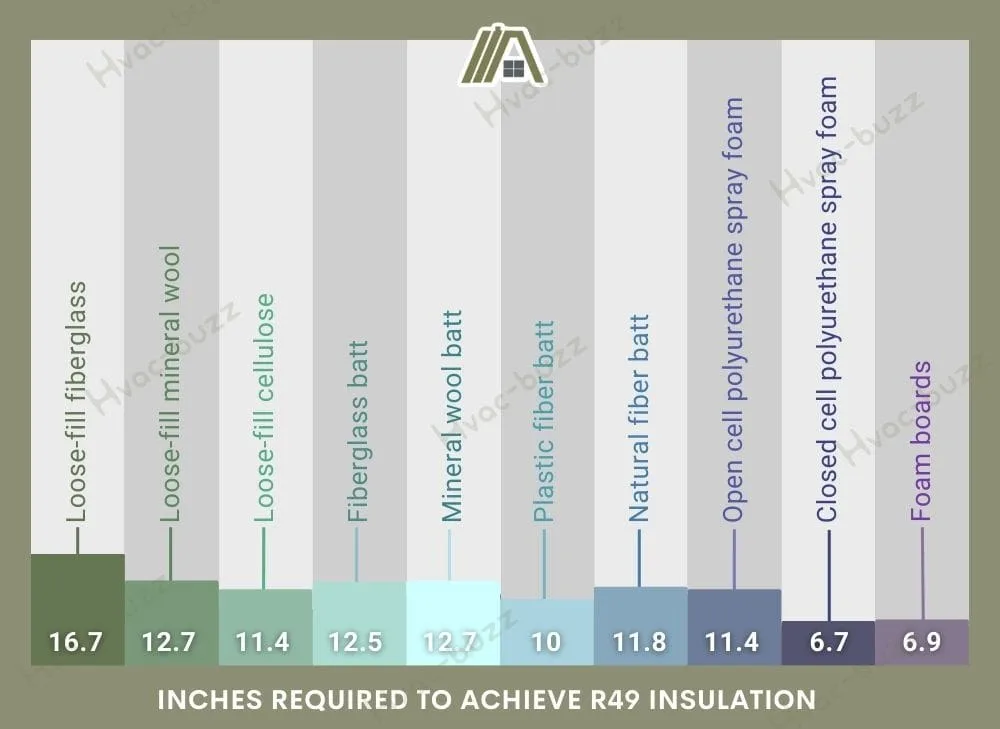

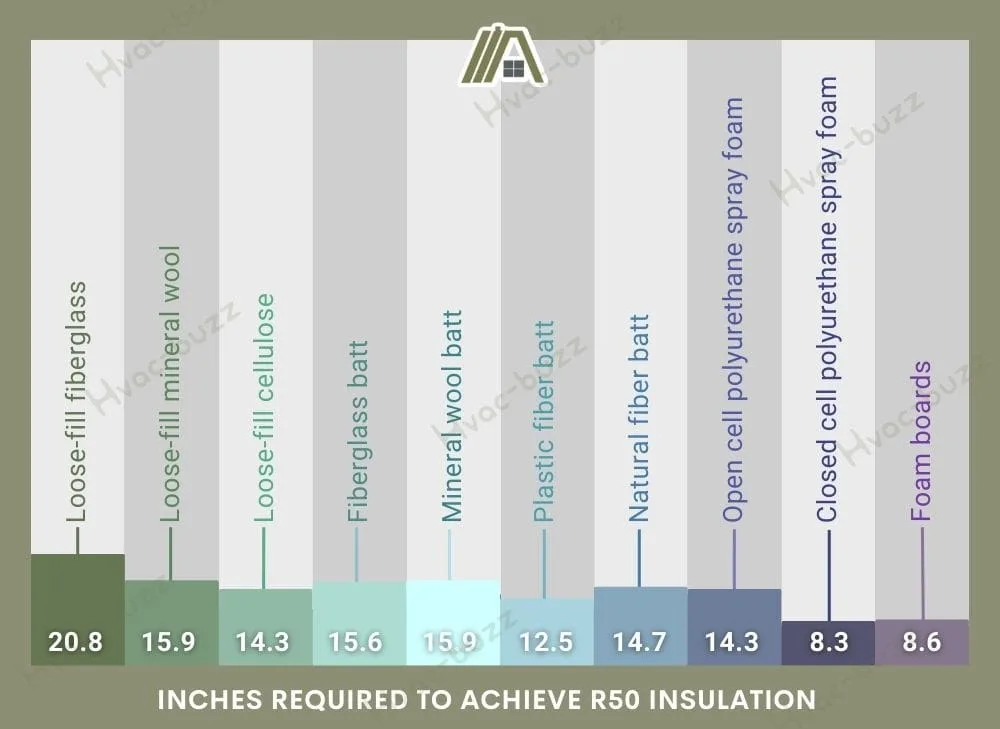

R49 is more commonly specified. R50 can be used instead, but the greater cost is not necessarily matched with greater insulating power. The thinnest layer achieving R50 is 8.3" with closed cell spray foam. The thickest layer achieving R50 is 20.8" with loose-fill fiberglass.

R49 vs R50

R50 insulation isn’t commonly discussed. R49 is much more common.

This is mostly because the increase from R49 to R50 doesn’t really offer a notable difference as far as improved function of the insulation. It would be like adding more insulation (so more cost) for essentially the same perks as what is offered with slightly less insulation.

It is also easier to find sellers who sell amounts of their insulation that equate to R49. It is more uncommon, on the other hand, to find that type of situation for R50.

Where Is R49/R50 Insulation Required?

Insulation R-values of 49 and 50 are relatively heavy-duty ratings.

Both R49 and R50 stop around 98-99% of the heat that could pass through solid materials.

Having higher insulation ratings, R49 or R50 insulation is most commonly used in attics. This will be discussed further below.

It is important to note that R49 and R50 insulation isn’t required everywhere in the house, and only in certain climate zones (also to be discussed).

This is to say that it is important for one to check local codes to see what the particular requirements are for your area.

R49/R50 Insulation Is Primarily Used in Attics

R49 and R50 insulation is mostly used in attics and ceilings. This is because a great deal of heat can be lost through these high points, so having a thicker amount of insulation there is more important for keeping heat in.

Attics also tend to hold a lot of heat. So, thick insulation is important in an attic in order to protect the areas of the home that have a regulated temperature.

For example, in a hot summer if you had your air conditioning on and the house was kept at 68 °F, the attic may still be extremely warm. It is not uncommon for attics to reach temperatures of 140 °F!

This heat can affect the temperature of rooms below it, making your HVAC system work harder to maintain the low desired temperature.

R49 or R50 insulation is then very valuable as it prevents the extreme heat in the attic from impacting the areas of the home that are trying to be kept cool.

Only Some Climate Zones Require R49/R50

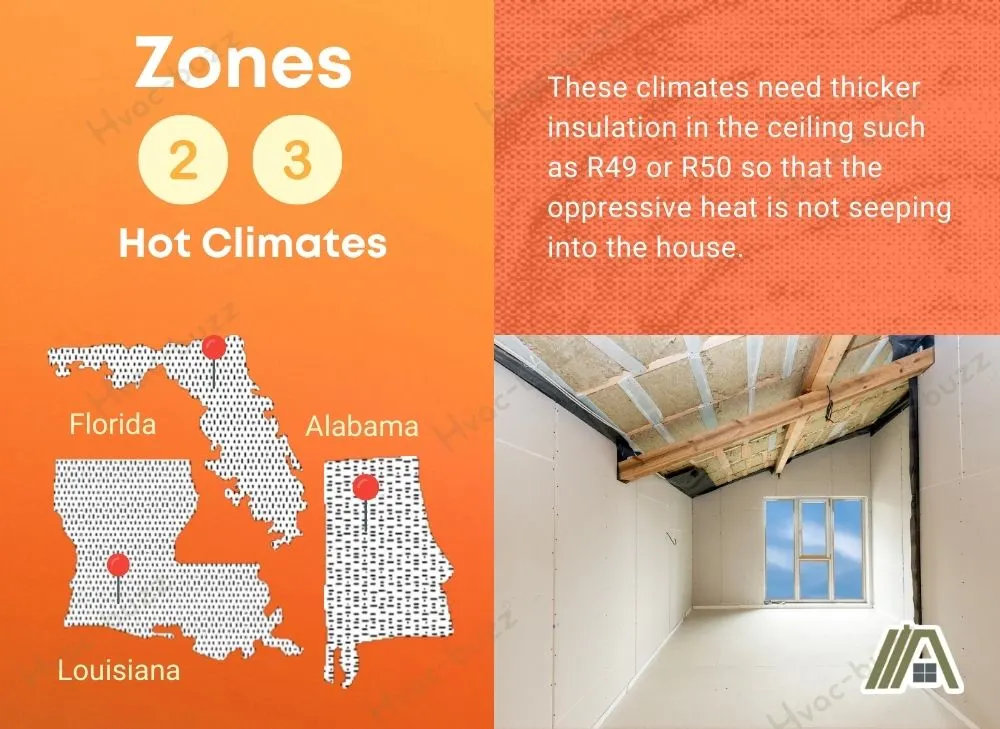

Only certain climate zones require R49 or R50 insulation. Table N1102.1.3 of the International Residential Code (IRC) explicitly explains these regulations.

R49 is only required in the ceilings of zones 2 and 3 (which are hot climates). R50 is not explicitly required anywhere, but could be used in place of R49.

Some states included in zones 2 and 3 are Florida, Louisiana, and Alabama. These climates need thicker insulation in the ceiling so that the oppressive heat, which is so common there, is not seeping into the house and impacting the temperature within the home.

Having thicker insulation in the ceilings and attics can also be helpful in reducing the noise of weather. Specifically in zones 2 and 3, rain is extremely common, which could be quite noisy. But having thicker insulation will help reduce weather-related noises.

R49 and R50 Insulation Thickness Guide: Table

| Insulation Type | Inherent R-value (per inch thickness) | Thickness to achieve R49 | Thickness to achieve R50 | Best-selling option |

| Loose-fill fiberglass | 2.2-2.7 | ± 16.7″ | ± 20.8″ | Owens corning 19 |

| Loose-fill mineral wool | 3-3.3 | ± 12.7″ | ± 15.9″ | R15 comfortbatt |

| Loose-fill cellulose | 3.2-3.8 | ± 11.4″ | ± 14.3″ | Borate only cellulose |

| Fiberglass batt (amazon link) | 3.1-3.4 | ± 12.5″ | ± 15.6″ | Knauf insulation EcoBatt |

| Mineral wool batt | 3-3.3 | ± 12.7″ | ± 15.9″ | Havelock Wool |

| Plastic fiber batt | 3.8-4.3 | ± 10″ | ± 12.5″ | JM Comfort Therm Fiberglass |

| Natural fiber batt | 3.4 | ± 11.8″ | ± 14.7″ | Owens Corning |

| Open cell polyurethane spray foam | 3.5 | ± 11.4″ | ± 14.3″ | Loctite tite Foam |

| Closed cell polyurethane spray foam (amazon link) | 5-7 | ± 6.7″ | ± 8.3″ | Tiger foam |

| Foam boards | 3.6-8 | ± 6.9″ | ± 8.6″ | SilveRboard |

Sources

https://www.tfofl.com/how-insulation-works