Heat pump dryers are marketed with two main benefits. Manufacturers claim that these dryers are the most eco-friendly and energy-efficient dryers on the market, and they are ventless. However, they are the most expensive to buy, they all take a long time to dry clothes, and they have smaller capacities.

I can see that not having to install a whole ducting system saves money. But longer drying times and more loads are typically associated with higher energy consumption, and the machine is definitely more expensive—we can’t forget this. So, are the claims to cost-effectiveness actually true?

Per load and year, heat pump dryers costs less than gas dryers but more than electric dryers. However, they have almost double the projected lifespan. They are definitely cheaper than gas but the lifespan costs are similar to electric models.

Energy-Efficiency Attributed to Heat Pump Technology

Although heat pumps are known for their long drying times, this does not mean that they are less efficient than other dryers.

On the contrary, heat pumps are more efficient than most dryers. This is because they recycle their air.

Heat pump dryers are ventless, and their design in achieving this ventless state allows them to reuse air.

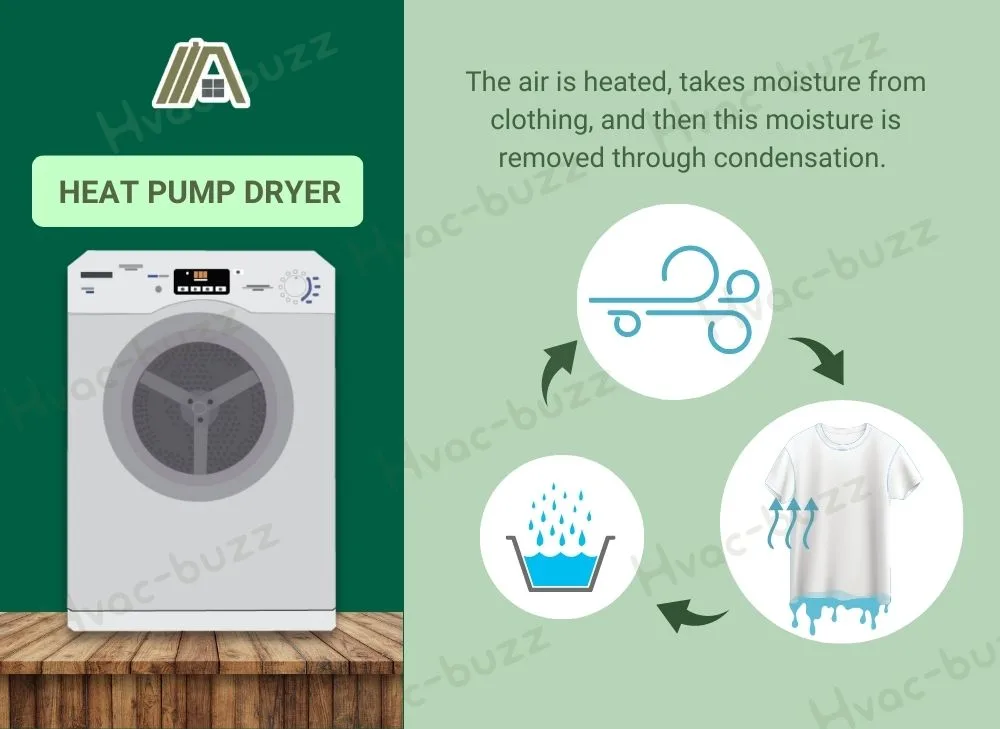

The air is heated, takes moisture from clothing, and then this moisture is removed through condensation.

This condensed water is removed after the cycle.

Once the moisture is removed, the same air can be cycled through the dryer again to remove more moisture from the clothing.

This process is called a closed-loop system since the air does not exit during this cycle.

The reason this system is known as energy-efficient is because of how the air is heated. The heat pump involves a refrigerant contained in coils.

These coils are wider and narrower in different parts. When the refrigerant passes through the narrower coils, it compresses, vaporizes, and increases in temperature. This heat is then transferred to the air passing over the coils before entering the drum.

When the air leaves the drum, it passes over the wider coils, which contain the less compressed and cooler liquid refrigerant. As it cools, the moisture condenses out.

Heat pump technology reduces up to 50% of energy use because it does not have to heat the air. It simply keeps the refrigerant cycling through the coils.

Hopefully, this explains the why, but what exactly does this mean as far as saving us money?

Requirements for Calculating Cost

Typical Drying Time of Heat Pump Dryers

Although the closed-loop system that heat pumps use means lots of saved energy, it unfortunately means longer drying times.

This is because the air used in heat pumps does not reach the same temperatures as their electric and gas counterparts.

Because of this, heat pump dryer drying times can range from an hour and 20 minutes to two hours.

Find out if Your Dryer Is Taking Too Long (Drying Time Table)

Amperage Rating of Heat Pump Dryers

The most common capacity for a heat pump dryer is about four cubic feet.

To find the average amperage ratings, I compared three popular brands that manufacture heat pump dryers. These brands are Whirlpool, Bosch, and Samsung.

The Whirlpool and Samsung heat pump dryers, both four cubic feet in capacity, had an amperage of 30 amps.

Although the Bosch heat pump dryer was also four cubic feet, its amperage was 15A.

With these three heat pump dryers being considered, the average would be about 25A.

Average Electricity Used Per Load

Given that heat pump dryers’ drying times are about 67% longer than electric or gas dryers’ drying times, it may seem that their electricity use per load would be higher.

However, because their drying process is so efficient, the heat pump uses less average electricity per load.

A heat pump dryer can use anywhere from 0.86 to 5.1 kilowatt-hours. On average, though a heat pump uses about 1.5 kilowatt-hours.

Given that a heat pump can run for 80 and 120 minutes, with 100 minutes being the average, we can calculate the average electricity used per load.

Dividing the average of 1.5 kilowatts-hours by the average running time (1.67 hours), we get 0.9 kilowatts per hour of energy for a full cycle.

How Often People Use Their Dryers

To further understand electricity usage and the costs associated with running a dryer, you need to factor in how often the dryer is used.

The average American household runs its dryer 283 times per year.

This means that the average American household is running their dryer about 23 times per month and about six times per week.

Lifespan of a Heat Pump Dryer

Because heat pump dryers are a somewhat new innovation in the dryer industry, they are likely to last longer than the average gas or electric dryer.

Heat pump dryers also often have a high upfront cost. Higher upfront costs can mean better-quality items, which can mean a longer lifespan.

More expensive and well-made parts will contribute to a higher cost but this can lead to the dryer lasting longer.

Regardless of the reason, heat pump dryers often last about 20 years.

Current Cost of Electricity

Although the cost of electricity can vary by state and electricity costs can vary over time, the average cost of electricity in the United States is about 16.09 cents per kilowatt-hour.

For businesses, this cost is about 13.04 cents per kilowatt-hour.

Cost of Heat Pump Dryers

With all of the requirements for calculating the cost of heat pump dryers met, we can start calculating the full cost of a heat pump dryer.

If a heat pump dryer uses about 1.5 kilowatt-hours per load of laundry and electricity costs about 16.09 cents per kilowatt-hour for a resident of the US, one load of laundry in a heat pump dryer costs about 24 cents.

Heat pump dryers often cost between $1,000 and $1,500. If the upfront cost of a heat pump dryer is $1,250 and the dryer lasts for 20 years, you will be paying about $62.50 a year for just the upfront cost.

If one load costs about 24 cents and the average American family runs their dryer about 283 times per year, the cost of running a heat pump dryer for a full year would be about $67.92.

This is just a bit more expensive than splitting up the purchasing price yearly.

Adding these two together to get a yearly cost to purchase and run the dryer, the total comes to $130.42.

If this heat pump lasts 20 years, you will have spent about $2,608.40 on this dryer in its entire lifetime.

How This Compares to Gas and Electric Dryers

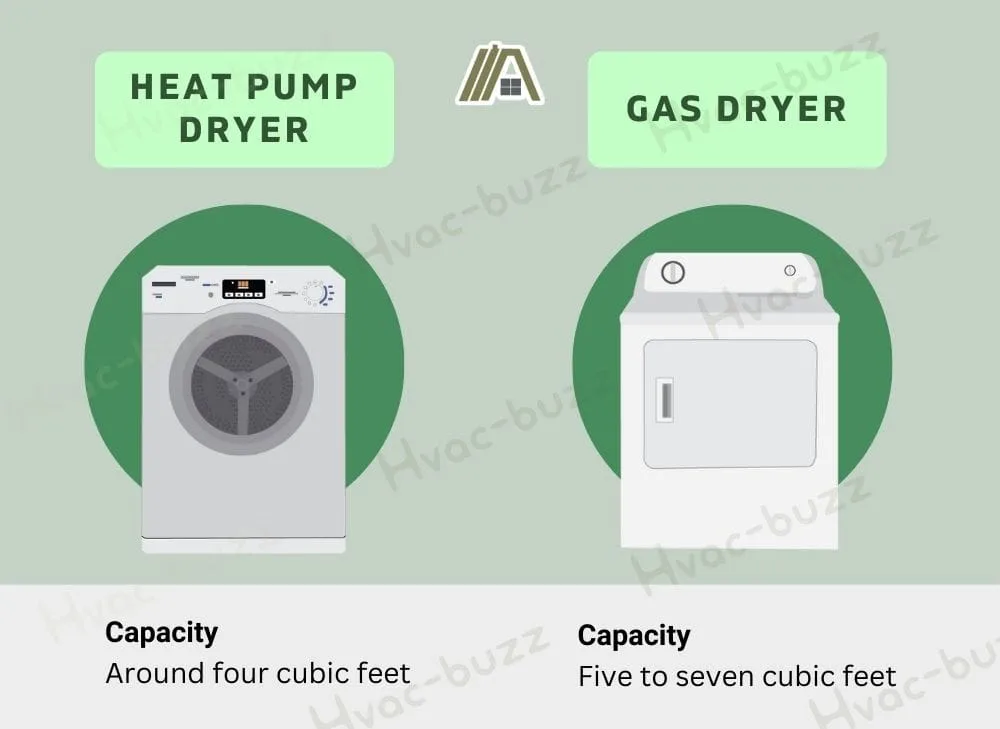

Before comparing the lifetime cost of a heat pump dryer to the cost of gas and electric dryers, it is important to note the capacity difference between heat pump and gas/electric dryers.

While a gas or electric dryer is often between five and seven cubic feet in capacity, a heat pump dryer is often around four cubic feet in capacity.

This means that, although the national average for dryer usage per year is about 283 loads, this is most likely assuming that a gas or electric dryer of higher capacity is being used.

If a heat pump dryer is used, the loads per year are likely to be higher than 283 loads since less laundry can fit in a heat pump dryer.

Nevertheless, comparing the cost of electricity per load (when using 283 loads per year) gives some unexpected results.

Gas dryers cost about 38 cents per load, which is higher than heat pumps’ 24 cents per load, which is expected. However, electric dryers cost about 21 cents per load on average. This is less than a heat pump dryer, which is not expected since heat pumps are more efficient.

This could have happened for a variety of reasons. Different averages for electricity could have been used as well as different averages for electricity cost.

The upfront cost of gas dryers ranges from $600 to $1,000.

The upfront cost of electric dryers ranges from $500 to $900.

While the average for a gas dryer is $800 and the average for an electric dryer is $700, the average cost of a heat pump dryer is $1,250. This is a large difference between these dryer types.

However, electric and gas dryers usually last about 10 years while heat pump dryers usually last about 20.

This means that you pay about $80 per year for a gas dryer, $70 per year for an electric dryer, and only $62.50 for a heat pump dryer.

The yearly cost for gas dryers (purchase and running) is approximately $176.22 and for electric dryers, it is $129.43.

Using this information, we can see that heat pump dryers are definitely cheaper than gas dryers. The difference in cost between electric and heat pump dryers appears to be negligible.

I would like to include a caveat here. Depending on the cost of electricity (and gas) in your area and the number of times you use your dryer and the actual duration of its functional life, heat pump dryers may well be as energy-efficient and money saving as claimed by manufacturers.

Sources

https://www.energystar.gov/products/heat_pump_dryer

https://www.build.com/bosch-wtg86403uc/s1762259?uid=4161061#overview

https://www.build.com/whirlpool-whd560chw/s1547542?uid=3643761#overview

https://www.linkedin.com/pulse/heat-pump-vs-condenser-dryer-which-more-energy-efficient-dwspl/

https://www.saveonenergy.com/electricity-rates/

https://www.attainablehome.com/do-heat-pump-dryers-last-longer-traditional/

Joan

Thursday 15th of February 2024

I just saw an article that said that electric dryers use 1.95 kwh per load. https://www.energysage.com/electricity/house-watts/how-many-watts-does-a-clothes-dryer-use/ Since I air dry most of my laundry on a drying rack, my dryer loads would easily fit in a 4 cu ft dryer. So if the average dryer is 6 cu ft it ends up balancing out if you always fill the dryer. So people may see energy savings with the heat pump dryer.

Michael Scott

Tuesday 26th of March 2024

Compared to traditional dryers people will see massive savings.