Kraft-faced insulation is insulation with a facing of paper vapor retarder that helps to ensure that the insulation stays dry. Typically, kraft-faced insulation is installed in exterior walls and attic ceilings, which are most vulnerable to condensation and vapor. Insulation for interior walls tends to be unfaced.

The kraft-paper facing on insulation changes things like fire risk, cost, and how and where the insulation can be installed. This all affects the need for and benefits of using it for interior walls.

Kraft-faced insulation can be used on interior walls. Faced insulation is more expensive. Faced insulation does not offer any other benefits besides being slightly easier to install.

No Rules Prohibiting Kraft Facing in Interior Walls

The International Residential Code (IRC) Section R702.7 comments on vapor retarders in exterior walls.

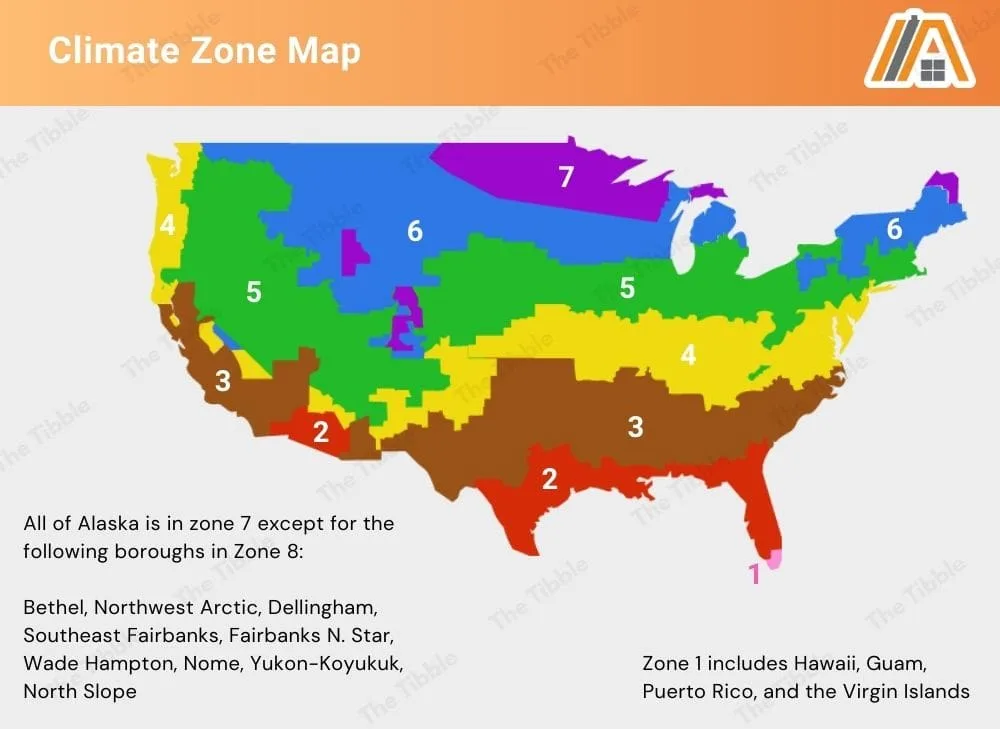

The IRC requires the use of Class I or II vapor retarders in exterior walls in cold climates (zones 5-8 and marine zone 4). Kraft facing is a Class II vapor retarder, so it is standard for exterior walls in colder states.

However, the IRC does not require or prohibit using vapor retarders, like kraft facing, in interior walls.

The fact that the IRC does not say anything about this practice reaffirms that it is not harmful to put kraft-faced insulation in interior walls.

Local codes sometimes differ from the IRC, but I have found no specific discussion of kraft-faced insulation (or vapor retarders in general) in interior walls. It is more likely that local code would differ in terms of rules about exterior walls.

For example, normally, vapor retarders/facing should be installed towards the interior of the exterior wall (this is what the IRC stipulates). But some states in hot and humid climates like the Gulf Coast have local codes that require the vapor retarder to be installed facing the outside.

It all depends on where the condensation is most likely to form and be problematic.

Considerations for This Insulation

Kraft Facing Can Only Be on One Side

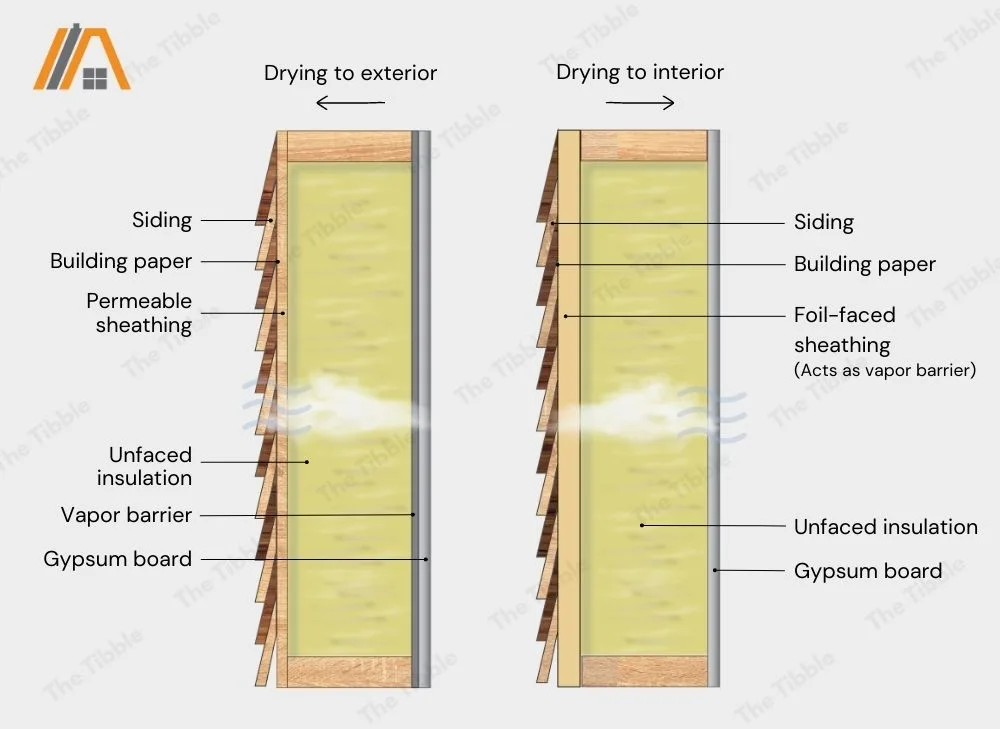

If you’re using Kraft-faced insulation for its vapor barrier properties because you’re concerned about moisture, it’s important to remember that more is not always better.

Putting a vapor retarder on both sides of a wall will trap moisture inside the insulation and wall cavity. A double vapor barrier basically creates a sandwich of soggy insulation with impermeable facing on either side.

Insulation will encounter moisture one way or another—from construction moisture that lingers, from water leaks, or from humidity and condensation. It needs to be able to escape through some kind of permeable material.

Condensation can cause the insulation to get moldy. Moisture also reduces the R-value of the insulation.

Basically, a wall needs to be able to dry in one direction. It either dries towards the exterior (cold climates) or towards the interior (warm climates).

As Joseph Lstiburek of Building Science Corporation tells us in his article “Macbeth Does Vapor Barriers”, remember the phrase “Double, Double, Toil and Trouble”!

The Paper Is Flammable

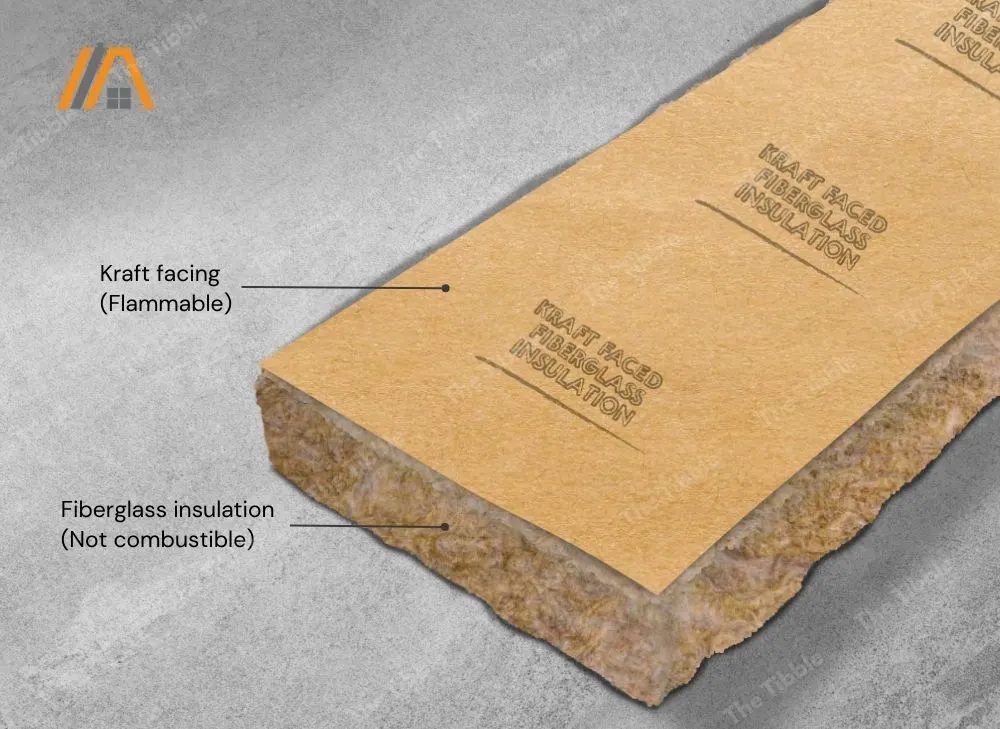

Almost all faced insulation is combustible. Paper and plastic facing will burn and, in the case of plastic facing, can release fumes while burning. Fiberglass insulation itself is not combustible, but as soon as you add Kraft facing, it causes the whole unit of insulation plus facing to be classed as flammable.

The facing side of faced insulation can never be left exposed. Only flame-resistant foil (FSK-25) facing can be left exposed. In fact, the paper itself will be printed with a label that says “Do not leave exposed.”

Basically, the kraft facing tells you “If you can read this, something is wrong.”

Even so, you probably wouldn’t leave kraft facing exposed if you’re using it in interior walls. Your interior walls would presumably be finished with drywall. Gypsum wallboard (another name for drywall) is an acceptable fire barrier for insulation.

People are more likely to leave kraft-faced insulation exposed in an unfinished attic, where it is a fire risk.

Turning the paper against the wall satisfies the IRC in terms of fire safety. But then there would be no point in installing it. You might as well just use un-faced.

It Is More Expensive to Buy Faced Insulation

Faced insulation is slightly more expensive than unfaced insulation. The cost difference is because the facing is an extra material that sometimes also needs to be treated or tested.

It’s a pretty minor difference, but we should never discount it, particularly for larger areas. Unfaced insulation typically costs about $0.50 to $1.75 per square foot. Faced insulation typically costs about $0.50 to $2.00 per square foot.

So, the cheapest faced insulation will be similar to the cheapest unfaced insulation. The cost difference comes into play in the upper range of products.

The cost difference is worth it for exterior walls, especially in colder climates where you’re often required by code to have a vapor barrier on the warm-in-winter side of exterior walls.

If you had extra faced insulation left over, it would not hurt to use it in interior walls (as long as the vapor barrier is only on one side). But if you are buying insulation specifically for your interior walls, there is no particular reason to take on this additional cost.

Benefits of Kraft-Faced Insulation in Interior Walls

By far the main reason to use Kraft-faced insulation in interior walls is that it’s easier to install. The paper facing means that the insulation won’t fall down or sag like unfaced batts can do. Additionally, you can easily roll and cut faced insulation.

Most importantly, faced insulation can be easily stapled to the studs in a wall. You won’t need to wrestle with looser, less sturdy unfaced batts. So, if you’re a DIYer—especially if you don’t have much insulation experience—it might be worth it to spring for kraft-faced insulation.

It’s worth noting that Kraft-faced insulation is less sound-quieting than unfaced insulation. Still, there are ways of compensating for this and many contractors debate whether special sound-deadening insulation is even worth it.

Doubling up on layers of drywall can often be just as effective at sound control.

A vapor barrier can be helpful in walls between rooms that can get humid, such as bathrooms and kitchens. However, it is more common to rely on latex-based primers and paints as vapor barriers in these interior scenarios, instead of using faced insulation to create the vapor barrier.

Sources

https://www.jm.com/en/blog/2019/october/unfaced-vs–kraft-faced-insulation–what-s-the-difference-/

https://www.certainteed.com/insulation/installation-vapor-retarders/

https://www.westernliner.com/blog/what-is-a-vapor-barrier-and-why-might-you-need-one/