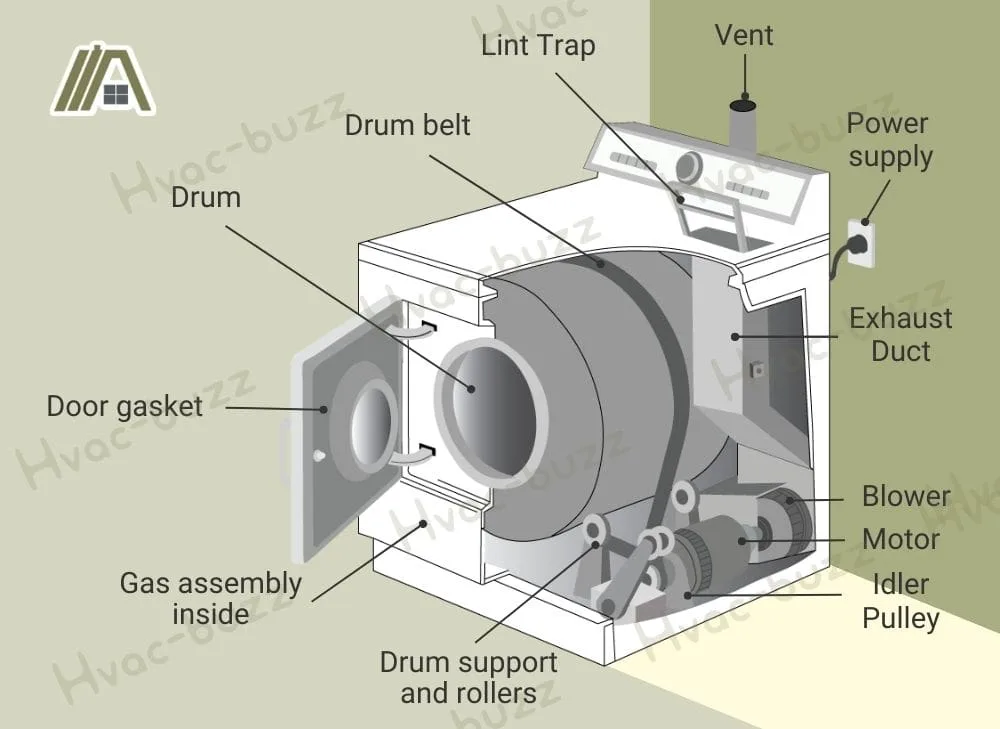

Knowing a little about your appliance and its inner workings is helpful. This can be an asset when it comes to identifying strange versus normal noises and when you are trying to identify what might be wrong with the appliance.

A gas dryer runs off relatively small amounts of electricity since the heat source is not electric. However, several mechanisms and components still require power to function together to get the job done and make the dryer safe.

Gas dryers are controlled through the electric control panel that dictates the settings. There is also a blower, gas assembly, motor, exhaust system, thermostat, and thermal fuse. Through these, air is pulled into the machine, heated, passed through the clothes, and exhausted safely.

Electric Panel Controls Settings

The dryer must be plugged into a 120V outlet with an electrical cord in order to provide power to the machine’s mechanism and control panel. This is why a gas dryer needs an electrical supply (even though it requires less than electric dryers) to power the circuit board for the settings.

When you power on the panel, electricity is directed to the circuit board in the back panel of the dryer.

The buttons on the control panel are connected to a series of wiring circuits that, in turn, connect to and control the various parts of the dryer, like the igniter and drum motor, by directing power to them.

The control panel combines with a mechanical timer and a thermostat. The timer regulates how long the dryer should be running, and the thermostat monitors the temperature, controlling the heat source to comply with your selected program.

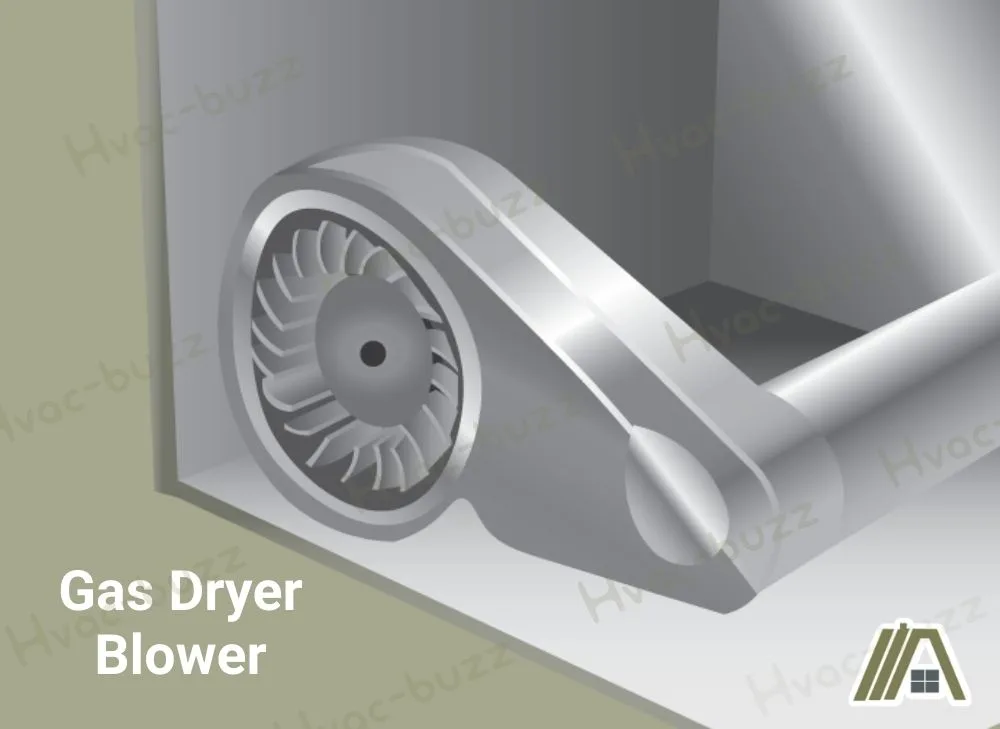

Blower

The blower is found in the lower portion of the appliance casing. This part of the machine is responsible for bringing air into the dryer, where it can be heated by the gas assembly and used to dry clothes.

This intake of air by the blower is essential for preventing the dryer burner from overheating.

The blower pulls dry air into the appliance, where it can be heated and passed through the wet clothes, and helps push the moist air to the exhaust vent.

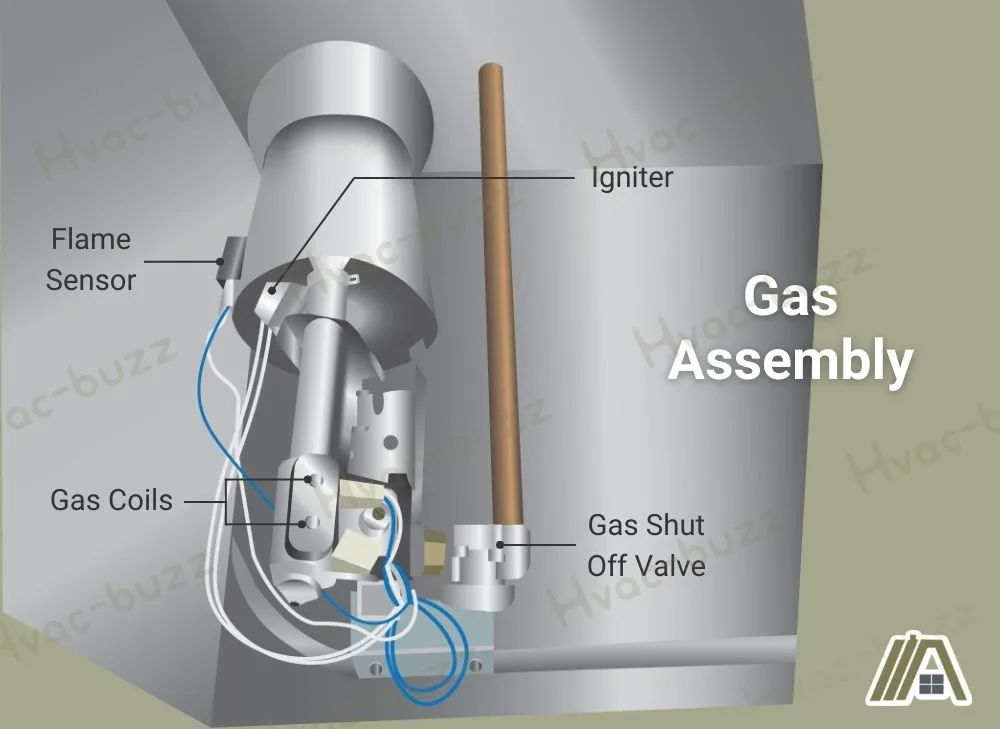

Gas Assembly

The electrical signals emitted from the control panel translate into activating the gas assembly.

The gas assembly is usually located under the tumbler, but the heat source also leads up the back panel of the machine, behind the tumbler.

The ignitor turns on (pilot lights have been phased out) before gas is allowed through the gas/burner valve into the burner housing through the solenoid (gas safety coils). This means that when the gas enters the housing, it can be utilized immediately.

The gas is ignited to create a source of heat that transfers to the air that is being blown through the tumbler.

This heat also closes the flame switch. This switch opens when it is hot through proximity to the ignitor. When cool, the switch closes, and electricity can be directed to the ignitor to heat it up.

If your gas dryer is whistling, then the issue is likely your gas assembly.

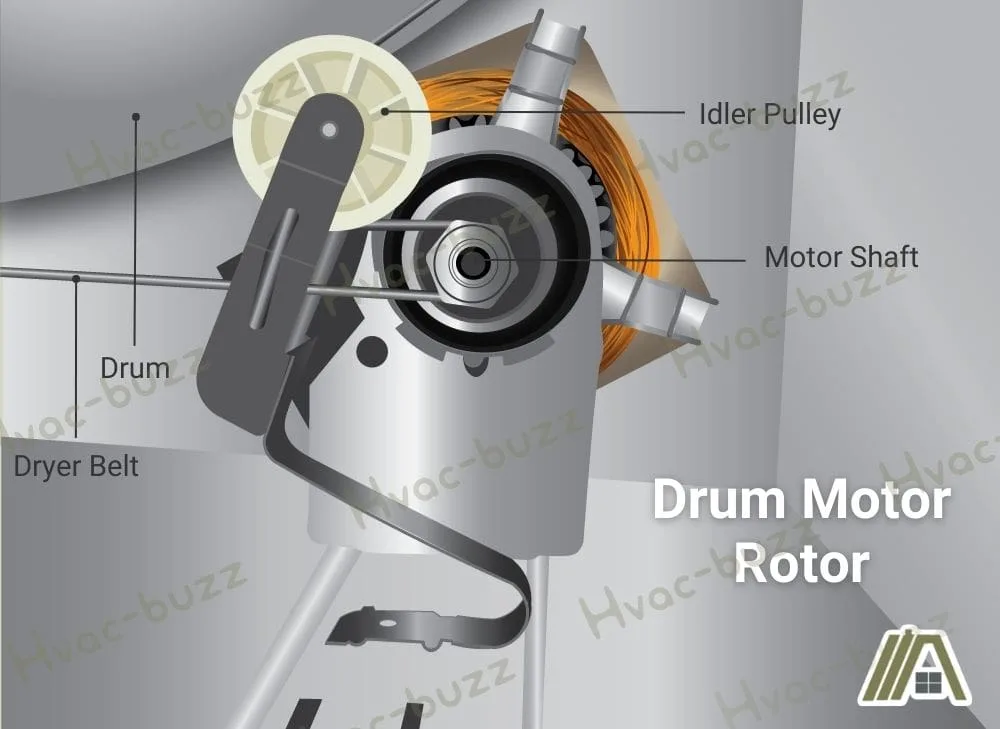

Drum Motor Rotor

Electrical signals also start the rotor motor of the drum. This motor rotates a driver pulley on which the dryer belt is hooked. This belt sits around the drum, causing the drum to spin when the belt moves.

A second idler pulley is also connected to the motor, which is responsible for creating the necessary tension that gives the belt leverage.

There are two motor switches within the dryer motor. These are closed (connected) by centrifugal force, meaning they close when the motor rotates correctly.

One switch allows the heat source to activate, and the second allows the motor to keep running when “start” is pressed. This second switch also prevents the dryer from running once the power has tripped to the appliance—you would need to press “start” again.

There is also a belt tension switch that trips the machine if the dryer belt breaks. This is a fire prevention feature because hot air is not circulating if the drum is not turning, and the clothes may ignite with the concentrated heat.

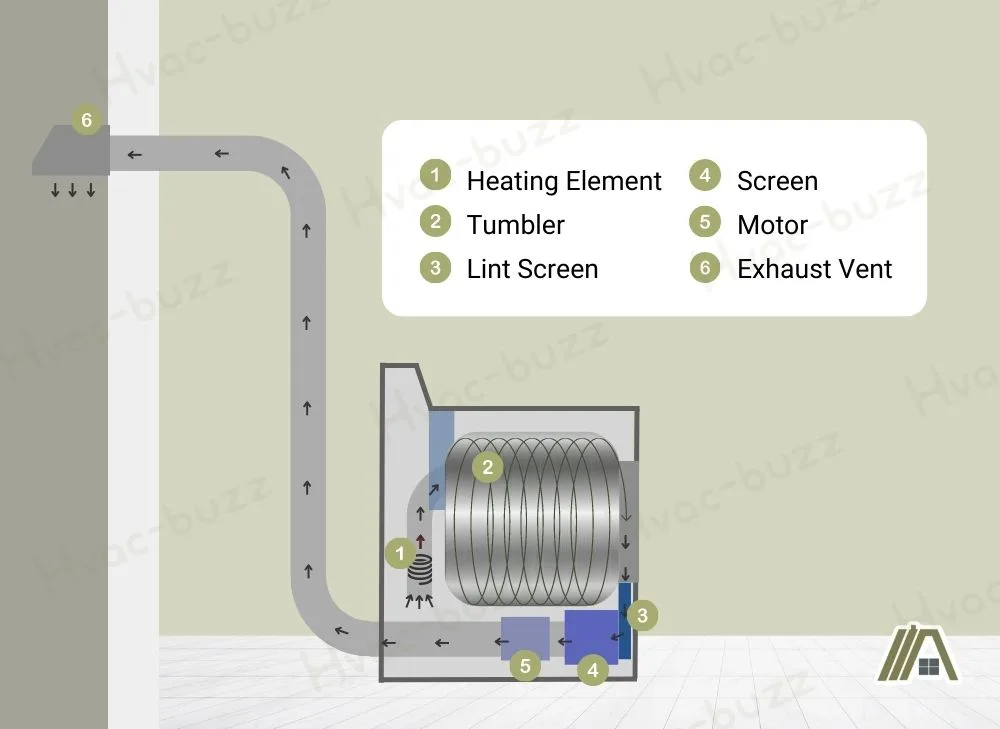

Airflow Through the Dryer

The air that is drawn into the dryer by the blower is directed over the gas assembly and heating element at the back of the dryer, where heat is transferred to the air.

Once the air is heated, it is pushed into the dryer drum by the blower. Inside the drum, it circulates through the tumbling clothes. The hot air evaporates moisture from the clothes in the drum and then passes out of the drum.

Once the humid air leaves the drum, it passes through the lint filter to remove the fibers loosened from the clothes during the wash and dry cycle. The air picks up these fine fibers and blows through the lint filter to deposit them in a safe area, keeping them away from excessive heat, which could start a fire.

Finally, the air passes through a duct within the dryer to a fan, where it is directed out the external dryer duct that vents humid air outdoors.

Gas Dryer | Is Venting Through a Chimney OK? (Code Examined)

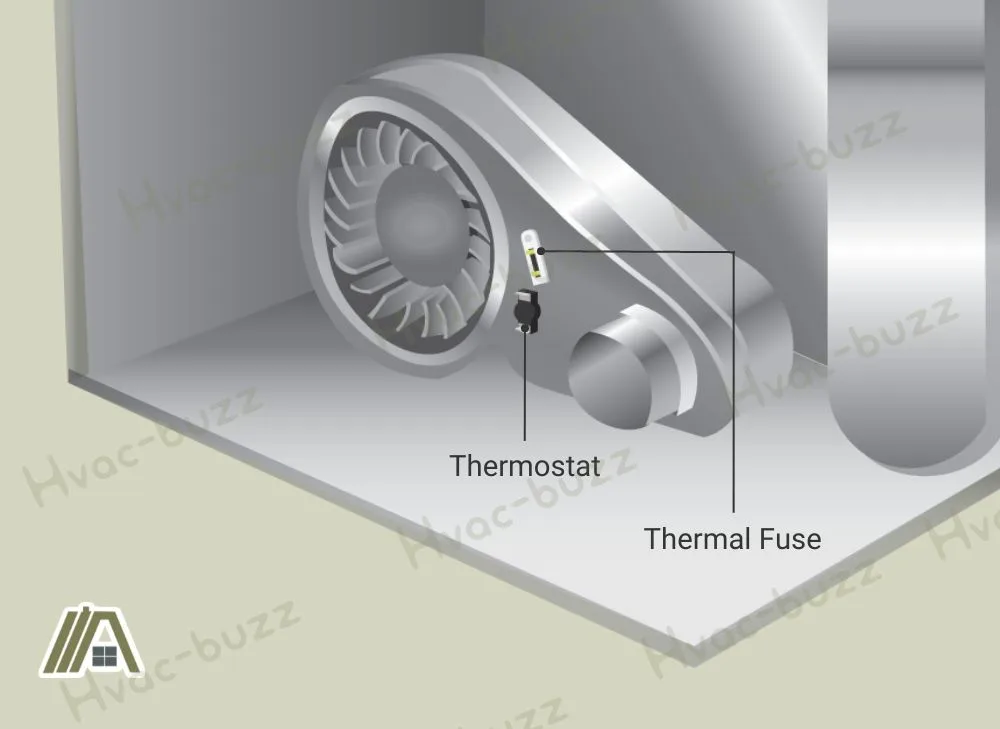

Thermostat and Thermal Fuse System

The thermostat and the thermal fuse in a gas dryer are part of the safety features and controls for the appliance.

This particular thermostat (also called the hi-limit thermostat) is designed to shut off the gas assembly (heat source) if it gets too hot.

This is done to prevent a fire from starting due to overheating, which can easily happen if there is insufficient airflow for the gas assembly. The air around the temperature sensor there will then measure above the heat limit.

The thermal fuse performs a similar action but with the appliance, not the gas. If the machine gets too hot, the thermal fuse will blow, cutting off power to the dryer motor. This will likely happen if the dryer exhaust vent gets blocked and the hot air cannot be filtered out correctly.

For more information on the electrical requirements of gas dryers, you can check out Gas Dryer | Does It Need a Dedicated Circuit? (Code Examined).

Sources

https://www.whirlpool.com/blog/washers-and-dryers/parts-of-a-dryer.html

https://accreditedappliance.com/dryer-thermal-fuse-keeps-blowing-heres-why/

http://www.appliance-repair-it.com/clothes-dryers.html

https://home.howstuffworks.com/dryer.htm

https://applianceassistant.com/Dryer-Repair/How-Gas-Dryer-Parts-Work_pg2.php