There are many possible ventilation systems in a home, the most common of which are the HVAC system, the bathroom exhaust fan, the clothes dryer exhaust, and the kitchen range hood. As you can imagine, the different functions of these systems make their ducting requirements rather different as well. Yet, all ducting can be simplified into two categories: rigid and flexible.

Choosing the best type of ductwork for your ventilation system depends on unchanging factors, like the code requirements, as well as subjective factors, like your budget. Below you will find a comprehensive guide to what the building code says is required and how to choose flexible or rigid ductwork when you are allowed the choice.

Rigid ducts must be used for dryers and range hoods. They are recommended for hot air ducts. Bathrooms can use flexible or rigid. Flexible ducts are better for small budgets, confined spaces, and DIY installations. Rigid ducts are better for long distances, exposed areas, low maintenance, and lifespan.

Choosing Based on What Is Code-Compliant

The International Residential Code (IRC) determines what is acceptable when installing different materials in your home. It is important to consult with the code, specifically Chapter 15 and Chapter 16 to determine what ductwork is allowed because it may just make the choice for you.

These regulations by the IRC are meant to ensure safety within the home and as such need to be followed.

Rigid Ducting for Dryers

According to Section M1502.4.1 of the IRC, when it comes to clothes dryers:

“Exhaust ducts shall have a smooth interior finish and shall be constructed of metal not less than 0.0157 inch (0.3950mm) in thickness (No. 28 gauge).”

As flexible ducting is known for its accordion-style ridged inner and outer surface, it does not meet the requirements of being smooth, so flexible ducts cannot be used for venting dryers.

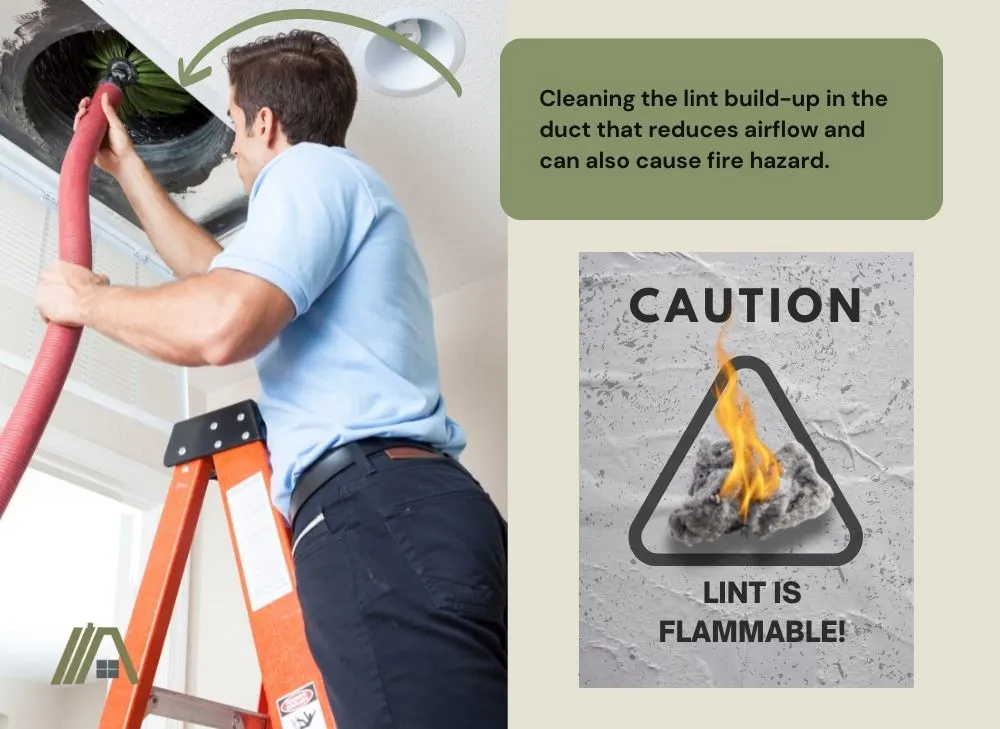

The reason why a smooth surface is mandatory is because of the fact that lint is moving through these ducts whenever the dryer is running. Lint is small and can easily get caught and build up on the ridges inside the flexible ducts. There are several negative consequences of this, including:

- Lint is flammable, so when it collects, it poses an in-duct fire hazard.

- The build-up of lint clogs the ducts, reducing airflow and leading to overheating of the machine.

Yes, flexible ducts are most commonly made from metal (aluminum foil), but they seldom meet the thickness requirement. As said above, the metal must be at least 0.0157″ thick. Most foil dryer ducts are much thinner than this, making them non-compliant.

The thickness of dryer ducts is important because they must be sturdy enough to maintain their shape (any deformation can create pockets in which lint and water can collect) and they must be thick enough to withstand the heat of the air passing through them.

Range Hoods Must Be Vented with Rigid Ductwork

The type of duct used with your range hood can directly influence its efficiency. Let’s look at what the IRC says about ducting for these appliances:

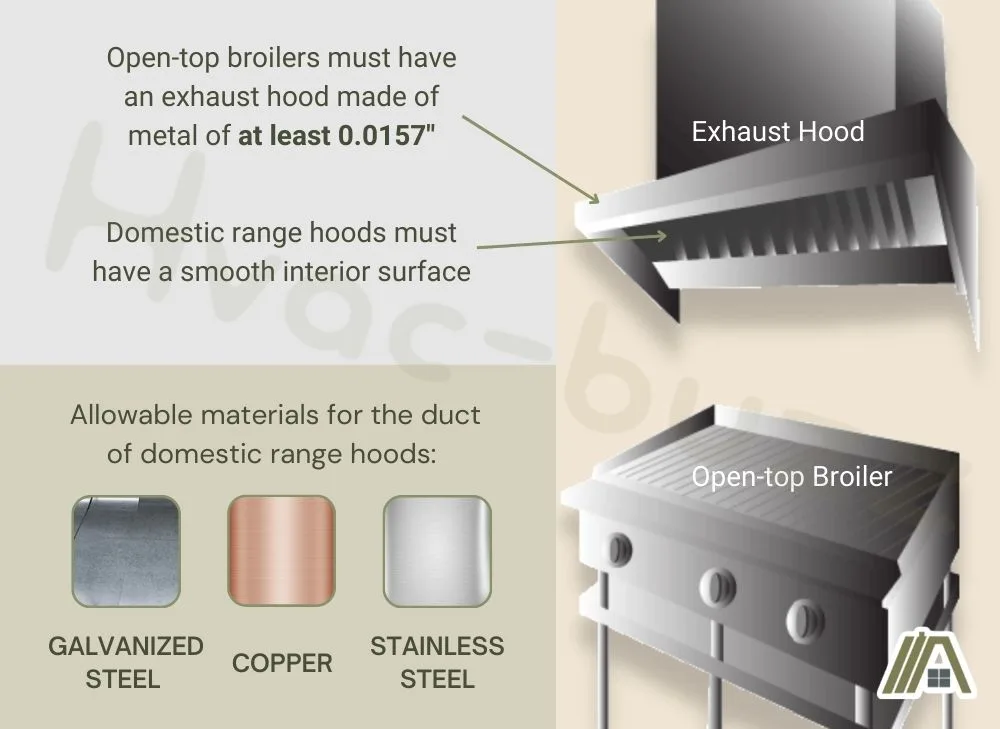

- Open-top broilers must have an exhaust hood made of metal of at least 0.0157″ (Section M1503.2.1).

- Domestic range hoods must have a smooth interior surface (Section M1503.3).

- Allowable materials are galvanized steel, stainless steel, and copper (Section M1503.4). As an exception, schedule 40 PVC meeting certain requirements can be used if the cooker has a downdraft exhaust system.

As even PVC is rigid, only rigid ducting can be used for domestic range hoods.

Flexible ducts would not be safe to use because the ridges reduce airflow efficiency and provide places for kitchen grease to build up. Not only this, but it also makes them much more difficult to clean. Grease build-up is often the most common cause of kitchen fires. It also becomes unhygienic, providing breeding grounds for bacteria and even mold.

What About Bathroom Fans?

When it comes to bathroom fan ductwork, you actually have a choice. You can use either flexible or rigid ducting as long as the ductwork is not too long and it leads outside.

Proper ventilation in the bathroom is incredibly important. Poor ventilation can lead to condensation, which can impact the structural integrity of your bathroom as well as become a breeding ground for mold and bacteria.

As long as your duct is installed correctly and expels air outdoors, either type will be effective.

Use Rigid Ductwork for Hot Air

Hot air is essential in HVAC systems, even the first letter in the name stands for “heating”. The temperature of the hot air going through your duct will ultimately impact the type of duct you use because it has to be durable enough to withstand the temperature of the air flowing through it.

Stainless steel rigid ducts can survive exposure to incredibly high temperatures, meaning that they will last a whole lot longer than flexible ducts, which are often prone to melting, cracking, and sagging.

If your heating ducts are compromised, hot air will escape. Your system’s efficiency will be compromised and the errant hot air can cause issues like overheating a crawlspace and leading to moisture build-up in construction.

Your home’s structural integrity may become compromised, you will struggle to maintain a comfortable temperature in the home, and your energy bill will rise.

For hot air, it is recommended to use a rigid duct to ensure the ultimate safety of your home.

Factors to Consider When Choosing Duct Material

Besides what the regulations stipulate, there are a number of other factors to consider when choosing your duct material. While the above information may make you think that there is no point to flexible ducting, it does have its pros as well as the cons.

The best way to decide is to have a look at these different factors and see which duct ticks the most boxes for your situation.

Your Ductwork Budget

After consulting your local building code, your budget may be the very next thing you consider.

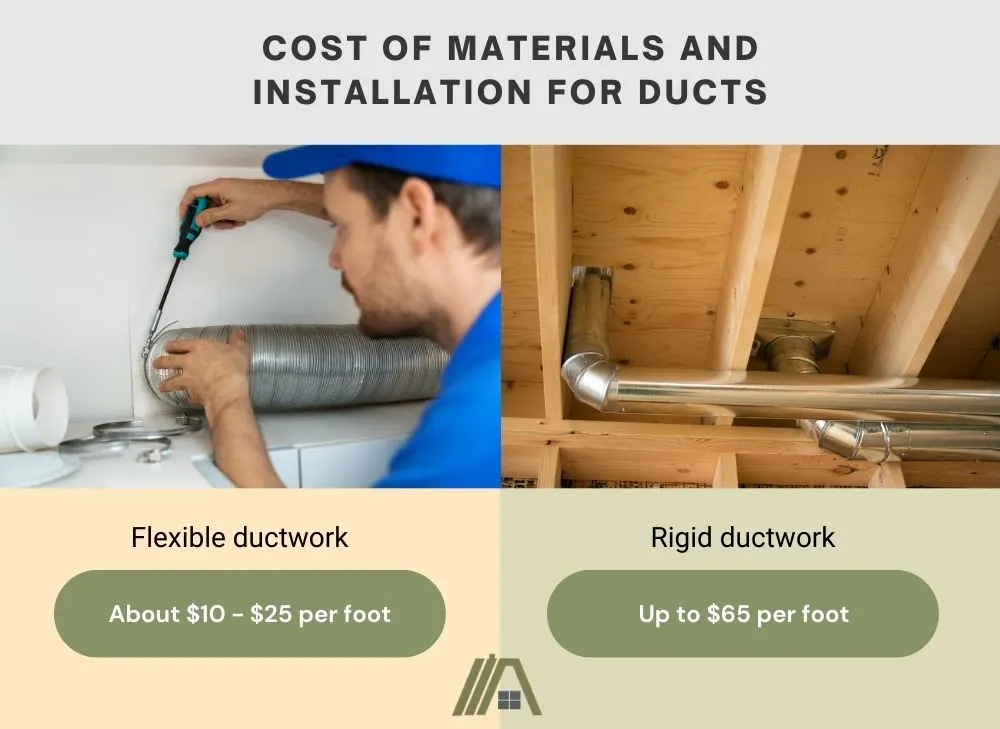

Flexible ductwork is cheaper to buy as it is made of cheaper materials. It is also easier and thus cheaper to install as it is lightweight and doesn’t require as much cutting and connecting as rigid ducting.

On average, the pricing from any store is going to start at around $1.5 per foot and even really high-grade flexible ducting shouldn’t cost you more than $5 per foot.

With installation, the price rises, but as mentioned, flexible ducts are easier to install, so the labor costs will be lower. The cost of the materials and installation will likely be between $10 and $25 per foot.

It’s also quite easy to source—you can even buy it from online stores, like Amazon.

- Designed for ventilation applications including HVAC, dryer, grow rooms and tents.

- Four layer design makes it more durable and resistant to leaks, tears, and cuts.

- Steel-wire spiral structure is flexible and easy-to-install in hard to reach places.

- Constructed of Aluminum and thermoplastic, tube can be shortened for various applications.

Last update on 2024-03-27 / Affiliate links / Images from Amazon Product Advertising API

Rigid ductwork is more costly to produce, transport, and install, thus making it more expensive than flexible ductwork overall.

Rigid metal ductwork can cost anywhere between $5 and $20 per foot depending on the type and quality of metal used. With installation costs, you could be looking at up to $65 per foot!

Looking purely at the budget, flexible ducting is your best bet if money is a constraining factor. However, as you will see later, this may only be a present saving as opposed to a long-term one.

Venting Distance

You are only allowed to lay a certain length of ductwork before it becomes too long to allow sufficient airflow and effective ventilation.

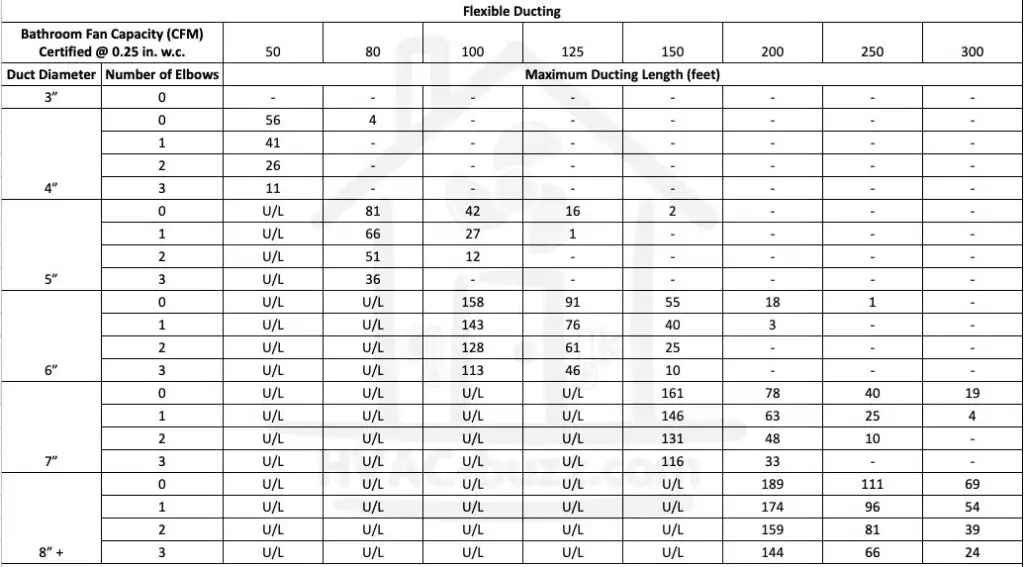

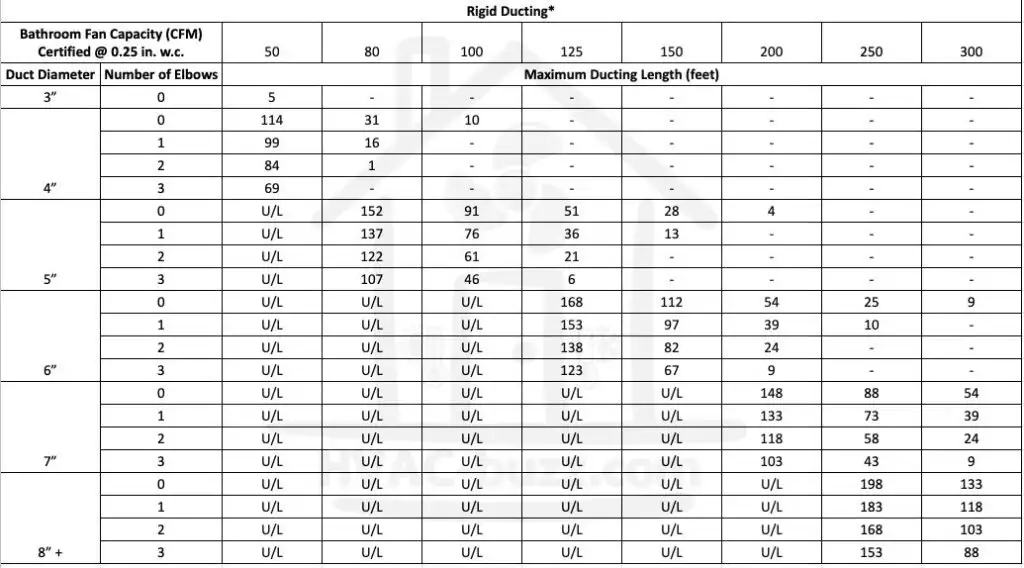

The allowable length differs based on the size of the fan powering the airflow and diminishes with each bend or elbow. You can see the below tables, based on Table M1504.2 of the IRC for the allowable lengths.

Flexible Duct Length Sizing Table

Rigid Duct Length Sizing Table

Using smooth wall/rigid ductwork allows for longer lengths to be used because there are no internal ridges that reduce airflow velocity as there are in flexible ductwork.

Size of the Spaces the Duct Runs Through

Flexible ducting is a better alternative than rigid ducting in small spaces that are difficult to work in.

The flexibility allows for easier manipulation in hard-to-reach places like small crawl spaces and you can bend it instead of having to cut the duct and connect the two sides using an elbow as is necessary with rigid ducts. Such a task is difficult when you cannot reach your hands around the duct and you are working on your stomach.

However, the flexible ducting should not be bent too many times as each bend is considered to be an elbow and the airflow velocity and allowable length are reduced. Furthermore, while the duct can be manipulated into a space, it should never be compressed.

Does It Run Through a Living Area?

If you have converted your attic or basement into a living area but left the ductwork exposed, then I recommend rigid ducting.

Rigid ducting looks neater and is typically better at containing heat than flexible ducts. It is also easier to paint, which can be used to “hide” the ductwork.

You don’t want to be sitting in your attic studio being fried by the hot air pumping through the duct beside you. Insulation will help with this immensely, but starting with rigid ducting is better.

Furthermore, if you are living in a space, then you are more likely to bump or otherwise come into contact with the duct. If you accidentally shove a pool cue into a rigid duct, it will likely bang, maybe dent, but remain intact. Doing the same to a flexible duct can lead to punctures, tears, movement, or deformation.

Can Animals Access It Easily?

Animals are attracted to the areas in our homes that are warm, damp, and mostly undisturbed. These coincide with the places where ventilation ducting runs. Indeed, the ductwork can contribute to the heat and moisture in these areas (although, this typically indicates a problem or a need for duct insulation).

If your ducting runs through a space that animals can access, then rigid ducting, preferably metal, is a much better choice. Animals like rats, mice, raccoons, and squirrels can chew through flexible ducting much more easily.

Holes in ventilation systems mean uncontrolled movement of hot and moisture- or grease-laden air, reduced energy efficiency, increased running costs, and the inconvenience of having to repair the ducts.

DIY vs Professional Installation

Earlier, I mentioned how much installation costs for flexible and rigid ducts. However, there is the option of installing them yourself, which is free and a very enticing option for the DIY enthusiast or homeowner with a tight budget.

If you are installing your own ducting, and you have the choice of either flexible or rigid, I recommend opting for flexible. It is much easier to work with and is more forgiving.

However, make sure that you are doing a proper job, otherwise, it is a false economy. According to Energy Star, you can lose 20-30% of conditioned air from poor connections and holes in the venting system. This means your electricity bill is higher each month and more frequent maintenance is required.

How Committed Are You to Maintenance?

Flexible ducts can collect dust and other particulate matter in the internal grooves. Water can also collect here, creating reservoirs for mold and bacteria to grow in. Time and the weight of pooling water can create sags in the ductwork, which make all the other problems worse.

Flexible ducting is also more prone to tearing or being crushed.

As a result, you need to constantly be monitoring your flexible ductwork, cleaning it out, and repairing any damage as it occurs. You may be able to do this yourself or you may have to pay someone else to do it.

Ultimately, rigid ducts, with their smooth interior surface and overall greater durability, require far less maintenance.

If you are someone who is going to install the ducts and forget about them for the next decade or so, then opt for rigid ducting.

How Long Will You Be Staying in the House?

If you are renovating a house to make it saleable, then use flexible ducting wherever possible. It is sufficient and allowed, but it won’t cost you as much as rigid ducting, and by the time it needs to be replaced, it won’t be on your to-do list.

Suppose, on the other hand, you are constructing your dream home, designed for generational use—an architectural heirloom as it were. In this case, definitely choose rigid ducting. It lasts much longer than flexible ducting.

Additionally, because it is you are benefiting from the extended lifespan, you can divide the initial purchase and installation costs over as many years as the ducts last, making it really cost-effective.

Pros and Cons Summary

Flexible Ductwork

| PROS | CONS |

| Inexpensive | Not very durable |

| Easier and quicker to install | Prone to mold growth |

| Easy to maneuver into tight spaces | Easily bendable, which can cause tears |

| Easy to access and transport | Prone to kinks and breakage, which impacts airflow |

| Pliable; can be used to vent places rigid ducts can’t | Requires regular maintenance |

| Lightweight | Repairs and replacements are required regularly |

| Many different materials are available | Creates resistance to airflow; can become energy inefficient |

| Prone to making noise |

Rigid Ductwork

| PROS | CONS |

| Durable and long-lasting | More expensive |

| Little maintenance required | Installation is more expensive and time-consuming |

| Resistant to mold growth | Heavy and difficult to transport |

| Minimal airflow resistance; energy saving | |

| Because energy is saved, your energy bill is less costly | |

| Longer lengths can be used | |

| Adheres to most IRC regulations | |

| Rustproof | |

| Quiet |