Squealing, thumping, scratching, or banging are all signs that there’s an issue with your dryer belt. Many of these issues arise due to the belt being too loose.

While it may be pretty easy to identify that the belt is loose, you may not know what’s the reason behind it. Learning more about the inner workings of your dryer can save you time and money on dryer belt replacements. So, let’s look at why your dryer belt is loose and what you can do about it!

Once the belt is stretched out, nothing can be done to tighten it. However, a loose belt doesn’t always equal a stretched-out belt. If the belt is loose due to a broken pulley, not sitting on the pulley right, or it has slipped off due to motor malfunction, the belt might still be in good condition.

Do Dryer Belts Stretch Over Time?

First, let’s find out why the belt is stretched out.

If you don’t care feel free to scroll down.

What Are Dryer Belts Made From?

Dryer belts are essentially giant rubber bands, although they aren’t quite as stretchy. Despite this, dryer belts do still have some elasticity.

Since rubber is an elastic material, it is able to return to its original form after being stretched. This is an important quality that makes rubber an ideal material for a dryer belt – but why is that?

Well, a dryer belt uses a pulley system to rotate the drum. We will go into more detail about this pulley system below, but the important thing to note is that the dryer belt must be under tension in order for the system to work properly.

Because the dryer belt is elastic, it is able to be gently stretched over various parts in the pulley system without becoming loose as soon as it is set into place. Instead, it is constantly trying to shrink back to its original size, keeping itself taut.

This tension allows the belt to both operate the pulley system and keep itself held in place, so it does not slip around aided by the fact that rubber can grip the drum due to friction, and the belts are usually grooved to increase that grip.

Elasticity Means Stretching Is Possible

Rubber is a relatively durable material for something that is meant to flex. However, much like any other material, it still wears down over time.

Inside a dryer, the belt is exposed to several forces. These include heat and friction while the dryer is running. And, as discussed earlier, the belt is also always enduring a level of tension.

Over time, these forces break down the rubber. It is common for the dryer belt to fray over time thanks to the heat and friction. However, tension and age can also cause the belt to lose its elasticity.

This is because elastomers and plasticizers in rubber begin to oxidize over time. In less technical terms, the components that give rubber its elastic qualities begin to break down the longer they are exposed to air.

As rubber ages and breaks down, it may begin to dry up and crack. In the case of objects like dryer belts that are constantly being stretched under a level of tension, the rubber may stretch out and lose its ability to return to its original size as it ages.

What Happens When Dryer Belts Stretch?

The idler pulley can take up some of the slack from a loosening dryer belt, but at some point, it becomes too loose. Once a dryer belt has stretched out to this point, your dryer may undergo some problems, to say the least.

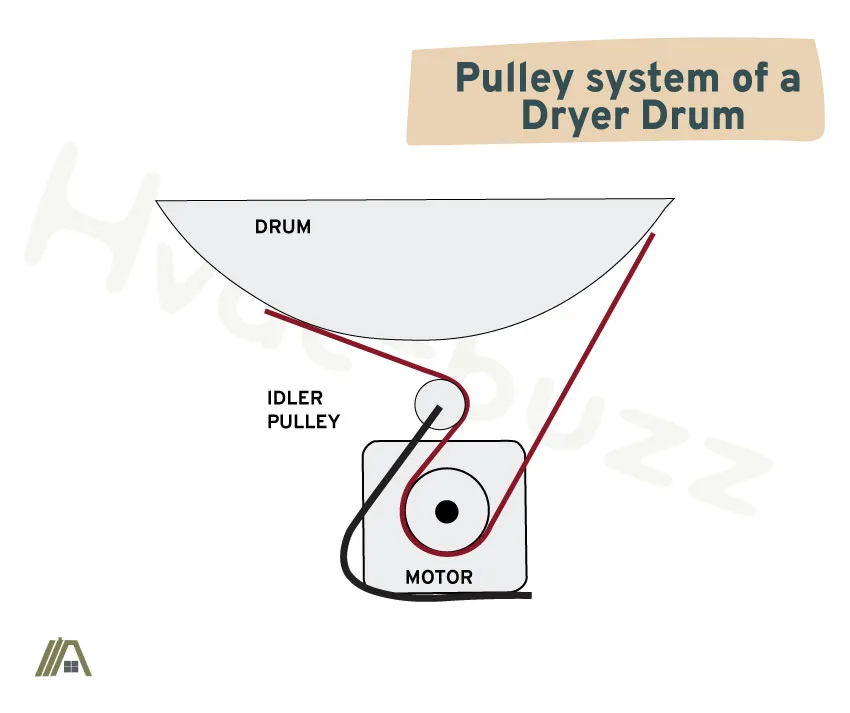

As mentioned earlier, clothing dryers can run thanks to their pulley system. There are three main components of this system: the drum, the dryer belt, and the drive pulley.

The belt wraps around the drum and the drive pulley, which is connected to a motor and creates the force that allows the drum to rotate.

The belt is also wrapped over a piece called the idler pulley, which picks up any remaining length or slack, and thus pulls the belt taut.

Without the idler pulley creating tension on the belt, the belt wouldn’t have enough grip to actually rotate the drum, and it would freely slide over the drum instead. The belt could even become displaced.

The same thing happens to a stretched-out belt. When your dryer belt loses its elasticity, it is usually no longer tight enough to rotate the drum, and it may even slip out of position.

Essentially, the belt must be kept constantly tensed in order for the pulley system inside the dryer to work.

You Cannot Tighten a Stretched Dryer Belt

There is no way to tighten a stretched dryer belt. Even if there was a way to do it, it would not be worth it.

If the dryer belt has become so stretched that it’s too loose to fit, then it’s probably also worn out and near the end of its life anyway. In this case, the best thing to do is to replace it.

Even if your dryer is relatively new, the belt can become stretched or break prematurely.

When the dryer belt is too loose, the idler pulley can’t create enough tension on the belt to turn the drum. This results in unnecessary stress on the pulley system and can cause some of its components to wear more quickly.

Some of the first warning signs this might be happening inside your dryer are unusual thumping, squeaking, or squealing noises while the dryer is running.

Similar results occur when the belt has too much tension. This also provokes excessive wear to the belt as well as all the other parts connected to it. Furthermore, the belt is exposed to high temperatures causing it to stretch.

Although you cannot tighten a belt if it has been stretched out, there are a few other possible causes why the belt may appear to be loose. Thus, it is good to check the inside of your dryer before going out and buying a replacement belt.

Other Reasons Why the Belt is Loose

Belt Is Not on Pulley Correctly

As stated earlier, the tension of the dryer belt is a key component to the belt functioning correctly. The tension comes from the pulley the belt is connected to, which can be adjusted if needed.

If the belt has become loose but is still in working condition, it’s most likely not sitting on the pulley right. This often happens due to incorrect installation.

Typically, a squealing sound can be heard as the belt is struggling to keep the drum in place. One way to remedy this situation is to push the idler pulley closer to the dryer’s motor.

Sometimes, if the belt has been out of place for too long, it may be easier to first take it off completely, verify it is still in good condition, and then reinstall it the right way. Once the dryer is open, this task is not too difficult.

When doing this, be sure the belt is facing inward. While looping the belt around the drum, you’ll also run it through the two pulleys; the idler pulley and the drive pulley. This is an important step as you have to make sure the belt is installed in a zig-zag or s-shaped fashion.

This video shows you how to install the belt correctly.

Belt Has Come off Pulley

If the belt has completely fallen off the pulley, the belt is most likely not the issue. It’s not uncommon for either the drive pulley, idler pulley, or some other component to be faulty. However, you will want to address what the problem is so that it doesn’t keep happening.

Oftentimes the belt will slip due to a short-circuited motor. If this happens, you’ll again be faced with the squealing sound as the belt struggles to keep the drum in place. A slipped belt left unchecked can result in the drum not rotating at all and will eventually loosen and damage the belt.

While getting the belt back onto the pulleys isn’t too difficult, locating what caused them to slip in the first place may be a bit more tricky. The pulley system is essential to a dryer’s functionality, and a technician may need to be consulted.

Pulley Is Broken

If you’ve identified that the belt and motor of your dryer are in working condition, the pulley system is likely the issue.

For example, Maytag dryers, like most dryers, have an idler pulley that consists of a wheel, spring, and bracket. If the wheel of this mechanism is broken, you’ll hear it. Again, the squealing, scraping, or thumping will immediately alert you of the problem.

If you’re able to get inside your dryer, test the idler pulley by trying to turn the wheel. If you feel resistance and need to force the wheel to rotate, it means the system is no good, and it needs to be replaced.

A faulty pulley system will most certainly result in a loose belt. However, be sure to check the belt for any excessive wear and tear. The belt might have been damaged if the problem was not addressed soon enough.

I have spoken a lot about the sounds that a dryer can make when there is an issue with the belt. This issue is not always that the belt is loose. I have written an article on diagnosing a noisy dryer belt to help you.

Sources

https://homeguides.sfgate.com/dryers-pulley-broken-41150.html

https://homesteady.com/info-8670523-dryer-belt-slipping.html

https://cementanswers.com/can-a-dryer-belt-stretch-out/

https://removeandreplace.com/2020/09/15/dryer-repair-does-your-dryer-belt-need-to-be-replaced/

https://everythingwhat.com/why-does-my-dryer-belt-keep-breaking

https://www.sidmartinbio.org/what-happens-if-dryer-belt-is-too-tight/