A strong wind can be noisy enough to drown out the sound of the TV or radio as it is. To add in rattling and banging coming from your bathroom fan, well, it’s enough to drive a person crazy.

While you can’t do anything about the howling of the wind outside, you can stop it from driving up through the bathroom fan ductwork. The possible causes and solutions depend on whether or not your bathroom fan ventilation system is equipped with a backdraft damper.

If there’s no backdraft damper, pressure changes and drafts entering the ducts create vibrations and noise. When dampers are present, blocked or broken flaps and operating mechanisms can allow air in as well. The flaps can also be picked up and dropped by the wind, producing a banging sound.

When There Is No Backdraft Damper

If you study bathroom exhaust fan termination requirements in the International Residential Code (IRC), which is applicable in all US states and territories with the exception of Wisconsin, you will find that backdraft dampers are not a requirement.

However, they are very helpful and are, thus, highly recommended. In my opinion, even the most advanced and perfectly sized bathroom fan is only half functional without a damper in the ductwork.

When we cover causes of noise when a backdraft damper is present, we will also talk a little bit about how these devices work.

For now, we’ll look at what causes wind-related noises in the absence of backdraft dampers.

Drafts and Air Pressure Changes

There’s really only one cause of noise in this case: drafts and air pressure changes.

When there is no damper, outside air can enter the bathroom fan’s ductwork, particularly when the fan is switched off.

When there are drafts or air pressure changes, this outside air can flow through the ductwork in an unsteady or turbulent manner, causing vibrations and noise.

These issues can be exacerbated when there are bends or obstructions in the ductwork as these can create additional turbulence and noise.

While the noise is most noticeable when the fan is off, the wind can also increase the noise level created by a fan that is operating.

When the air leaving the ducts collides with air that is being pushed into it, it creates pressure and pressure changes that rattle the ducts.

Additionally, the fan has to work extra hard to push the air out against the force of the incoming air, so it may produce whines and other sounds associated with overworked motors.

Solution and Future Prevention

There is only one effective solution to this problem. You need to install a backdraft damper. This device only allows air to flow out of the ducts when the fan is on.

Outside air has no access to the ducts, so it cannot rattle through the system or make the fan work harder to exhaust the bathroom air.

By installing and maintaining the damper, you also prevent the problem from arising again in the future.

Backdraft Damper Is Present

A backdraft damper is a device equipped with flaps that can only open one direction and which are typically only open when the fan is in operation.

The flaps only open towards the exterior of the house, so only air traveling out can be in the ducts. Outside air should not be able to enter.

There are multiple ways in which the flaps can operate:

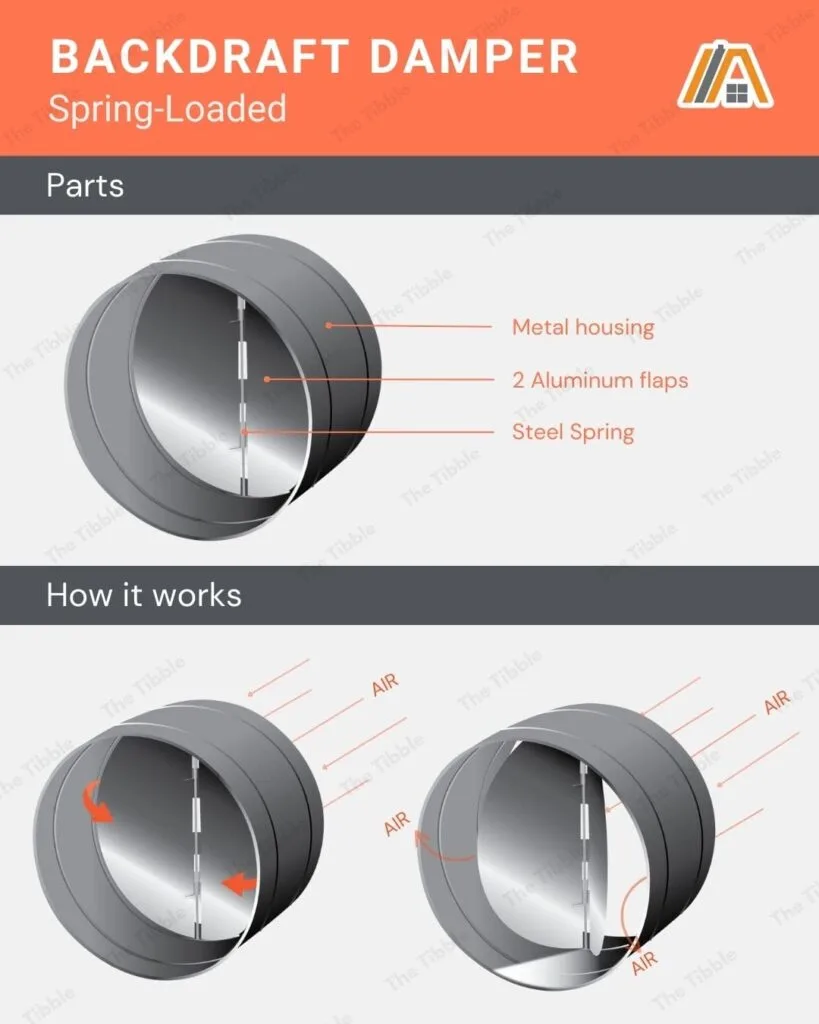

- Some are spring-loaded and push open when the pressure behind them increases past a certain point. So, the force of the air being driven through the ducts by the fan overcomes the force exerted by the flap springs and they open.

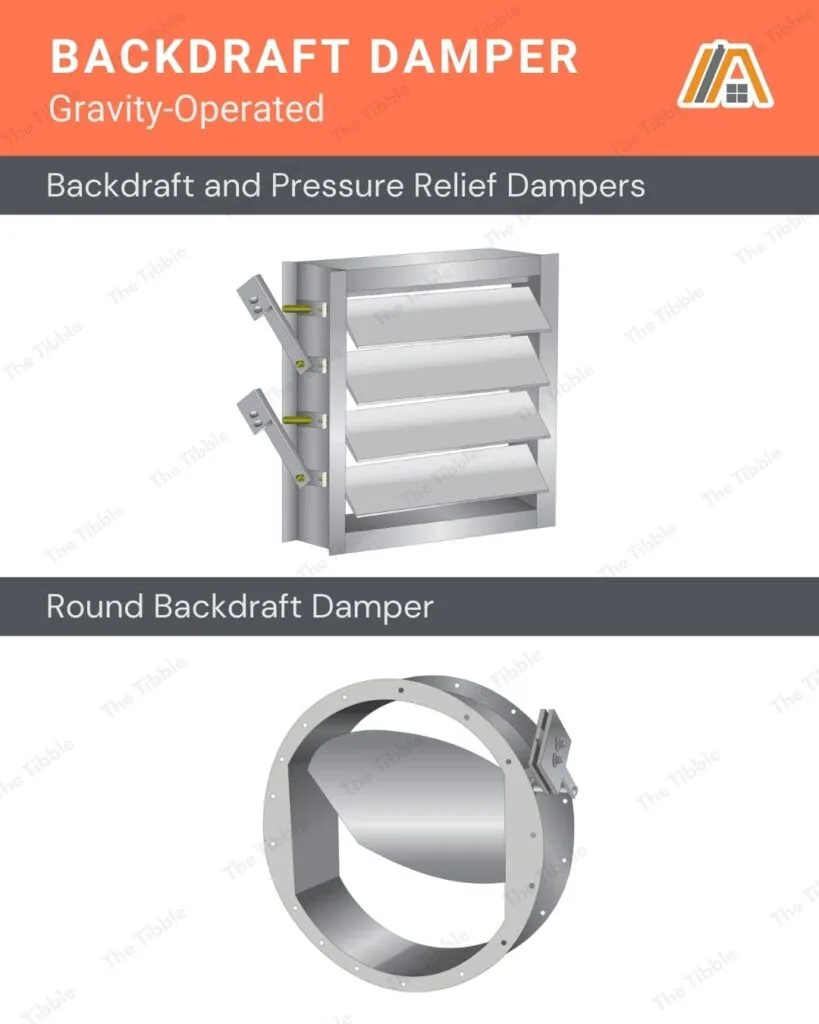

- Some dampers are equipped with hinged, gravity-operated flaps. The hinges are horizontal and cannot cross the midline, i.e., they can only be pushed out by the air exhausted from the bathroom. Once this pressure ceases, gravity causes the flaps to fall closed.

- Some dampers are electrically opened. Most often, the operation is linked to the fan’s. So, when the fan is turned on, a signal is sent to the damper to open. When the fan switches off, the damper closes, although there may be a slight delay to ensure all the steamy air is out before the flaps shut.

- ECONOMIC SOLUTION – Protect your comfort & your wallet by limiting heating and cooling expenses in your space. This cost-efficient zone damper limits the need for excessive HVAC use and keeps your...

- TOTAL ZONE CONTROL – This ZoneMaster gives you complete individual control over the climate in your space. Customize and maintain the temperature in specific rooms of your home with these zone...

- ENERGY EFFICIENT DESIGN – Take control of your comfort and preserve energy by using these automated duct dampers. When power is not supplied, the damper stays closed.

- FRESH AIR INTAKE – Improve the quality of air in your home by installing a fresh air intake system with a Suncourt motorized airflow damper. Once the damper is closed, it will block drafts, airflow...

Last update on 2024-03-27 / Affiliate links / Images from Amazon Product Advertising API

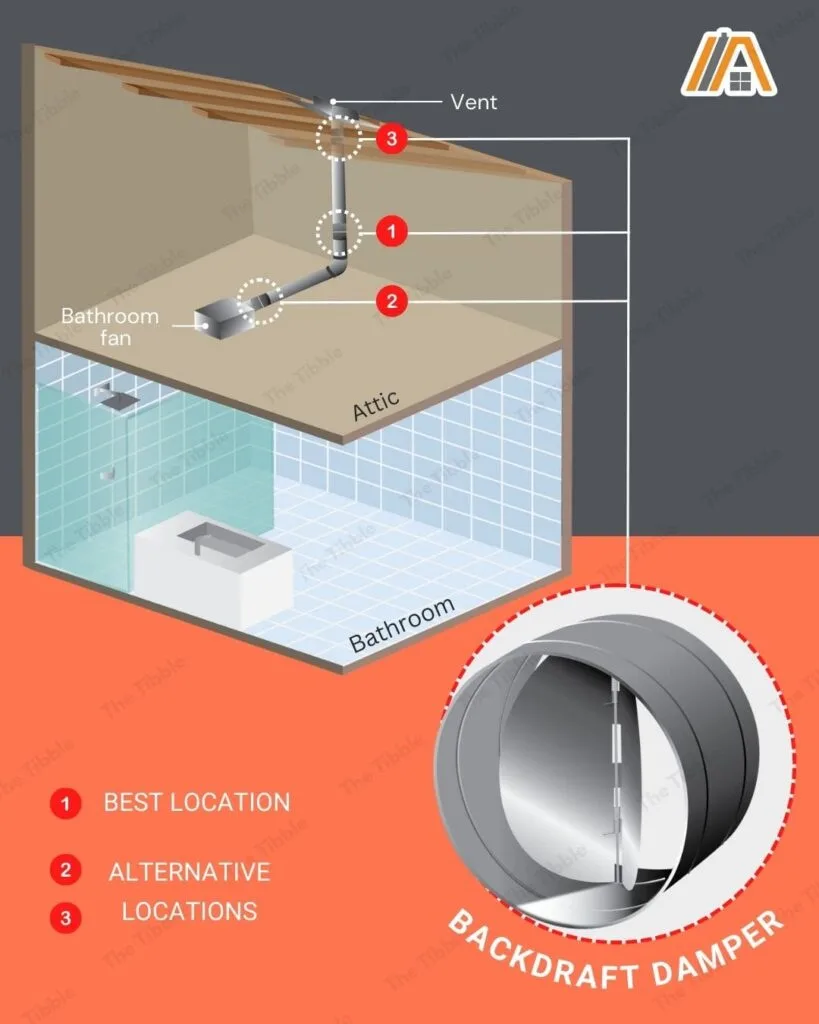

Backdraft dampers can be fitted at different places in the ventilation system, so keep that in mind when looking to check if you have one and identifying the most likely cause.

- Installation: Features a 4 or 6-inch duct adaptor ideal for renovations, assisted living and dorms

- Precision Spot Ventilation: Quiet and powerful ventilation while removing moisture and pollution

- Dual Sensor Technology: Provides built-in redundancy for automatic moisture and odor control

- Flexible Installation: Comes with Flex-Z Fast bracket for easy, fast and trouble-free installation

Last update on 2024-03-27 / Affiliate links / Images from Amazon Product Advertising API

Broken Backdraft Damper Flaps

If you are harassed by a noisy fan every time there is wind outside, it’s time to check your backdraft damper.

Regardless of the type of backdraft damper that you have, the flaps can break.

They can warp, crack, and chip, depending on the quality of the material, how well they are handled from production to installation to maintenance, and what kind of environment they are exposed to.

Harsh sun, frequent driving rain, debris tossed by strong winds, all of these things can weaken and damage the flaps of backdraft dampers.

Low-quality material is more likely to be influenced by these kinds of mechanical pressures and much more quickly.

Any production fault or damage during shipping, installation, or maintenance can immediately compromise the flaps or cause weakness that predisposes the flaps to failure.

Solution and Future Prevention

Unfortunately, repairing the flaps a backdraft damper is not a viable option. In these cases, you will need to replace the backdraft damper.

Future prevention involves choosing a good damper and maintaining it well.

I personally prefer the spring-operated backdraft dampers. They are more resistant to the effects of wind than gravity-operated dampers, and they function mechanically as opposed to electrically, so there is one less component that can go wrong. More on this in later sections.

I can recommend the AC Infinity spring-operated damper if you have round bathroom fan ducts.

It comes in three different sizes, four-inch, six-inch, and eight-inch, and it has a rubber seal for preventing leaks and drafts.

- An antidraft duct insert designed for use with range hoods, bathroom fans and other home HVAC applications.

- Features outer rubber gaskets that create an airtight seal and grip between the damper and ducts.

- Mounts horizontally or vertically to prevent backflow and debris from entering ducting.

- Galvanized steel body with spring-loaded aluminum damper blades that open with minimal airflow.

- An antidraft duct insert designed for use with range hoods, bathroom fans and other home HVAC applications.

- Features outer rubber gaskets that create an airtight seal and grip between the damper and ducts.

- Mounts horizontally or vertically to prevent backflow and debris from entering ducting.

- Galvanized steel body with spring-loaded aluminum damper blades that open with minimal airflow.

- An antidraft duct insert designed for use with range hoods, bathroom fans and other home HVAC applications.

- Features outer rubber gaskets that create an airtight seal and grip between the damper and ducts.

- Mounts horizontally or vertically to prevent backflow and debris from entering ducting.

- Galvanized steel body with spring-loaded aluminum damper blades that open with minimal airflow.

Last update on 2024-03-27 / Affiliate links / Images from Amazon Product Advertising API

The quality of the AC infinity dampers can prevent them from wearing out as quickly as cheaper versions. They are also less likely to start off with manufacturing or handling defects.

Obstructed Flaps

When you investigate your backdraft damper, you may be lucky enough to discover nothing wrong with the flaps other than the fact that they are being held open by an obstruction.

- Dirt can build up at the damper and prevent the flaps from sealing.

- Leaves can get wedged in the flaps after a storm.

- Insect carcasses can stop the flaps from closing properly.

- Birds and small mammals can build their nests in the duct and obstruct the damper flaps.

When the flaps are held open, outside air is able to enter the ductwork and create noise as described in the section on drafts and air pressure changes.

Solution and Future Prevention

Simply remove the obstructions with whatever tools will work without damaging the damper, and set up a regular checking schedule to ensure that it doesn’t happen again.

You can also cover the terminal vent with a screen to prevent larger debris and animals from getting to the damper.

Issues With the Flap Operating Mechanisms

Electrically-operated dampers can fail. The device may not receive or respond to the signal sent when the fan is turned off. The flaps can then remain open and outside air has access to the ductwork.

The failure of these electrical devices can be the result of manufacturing defects, handling/installation damage, power surges, water damage, etc.

Gravity-operated dampers cannot fail in the same way. They will always close once the pressure of outgoing air ceases.

However, they can fail by responding to the incorrect airflow.

Particularly if your damper is located at or near the terminal vent, strong enough gusts of air coming from the right direction can pick the flap up.

This has a two-fold implication on noise:

- Firstly, when the flaps are open, air can enter the ducts and rattle through the length of them.

- Secondly, when the flaps are dropped again as the gusts subside, it can create a banging noise, which reverberates through the ductwork.

The springs of a spring-operated damper can fail, meaning that they do not press the flaps all the way closed when the bathroom fan is switched off.

This allows air to flow into the ducts and cause vibrations and noises.

All things considered, I feel that a spring-operated damper is least likely to fail, which is why I previously claimed that it is my first choice.

If your bathroom fan is on its last legs anyway, you also have the option of installing a unit in which the exhaust fan comes with an integrated spring-loaded damper, such as the Panasonic FV-0511VQC1.

Solution and Future Prevention

If the flap-operating mechanisms of electric and spring-operated dampers are broken, then you will need to replace the whole device.

You might be able to repair the electrical unit of the former, but likely it is not worth the effort.

If your gravity-operated backdraft damper is playing up, however, there are some options other than replacement (with a different type of backdraft damper).

Foam Padding

If the issue is primarily the banging noise, you can use self-adhesive foam stripping or foam dots to stop the flaps from hitting metal-on-metal as they drop.

- SIZE OF THIS FOAM TAPE - 1 inch W x 1/8 inch T x 16.5 ft L x 2 rolls. You can cut the single-sided door weather stripping into any length you need by using a blade.

- STRONG ADHESIVE - The door weather stripping adopts a stronger adhesive backing which ensures the foam tape can stay in place without falling off once applied.

- GREEN MATERIAL - The high-density self-adhesive weather stripping is made from harmless CR foam and Neoprene. Excellent sealing quality, resistance to deformation feature, flame retardant, and can be...

- EASY TO USE - The release paper of this seal strip is easy to peel off, no tools or drilling needed. This foam sealing tape is suitable for most flat and smooth materials' surfaces like wood, metal,...

- Package include: one package includes 12 sheets double-sided adhesive foam dots, 200 pieces small adhesive foam dots per sheet, 2400 pieces small adhesive foam dots in total

- Eject 3D effect: our adhesive mounts are made of EVA foam, will add dimension to your craft with a slight 3D element, you can also stack the dots together to create more surprises

- Suitable size: each adhesive foam dot features round shape, general size to use, they work well on most paper, fabric, plastic, metal and wood surfaces; Please look at pictures for detailed size...

- Durable and sticky: our adhesive foam mount is sticky but photo safe, there is no glue reside so you don’t have to worry about the tape hurting your precious photos, quality material decides it can...

Last update on 2024-03-27 / Affiliate links / Images from Amazon Product Advertising API

Look where the contact point is and place the foam here. Be careful not to make it too thick. This will only make it easier for the wind to lift the flap up.

Unfortunately, these are typically only available in bulk, but they are not too expensive and as a DIY king/queen, I bet they will be a welcome addition to your supply collection.

Small Weights

Find an object that weighs enough to hold the flaps down against wind from the outside but is light enough not to prevent the flaps from opening in response to the pressure of the air exhausted from the bathroom.

You will likely need to test a number of objects before you find the correct one.

To test it, temporarily attach the object to the flap and turn the fan on. Wait for the system to get up to full strength and check if the damper is opening properly. Adjust the weight if necessary.

Additionally, you will have to wait until the next windy day to see if the weight is heavy enough to stop the wind from picking the damper flaps up.

A great option for the weight is a washer held on with a small bead of silicone. Washers come in many sizes, they sit flat against the damper, and they are readily available. You probably already have a good collection to test out at home.

Alternatively, you can look at wheel weights, which come with a waterproof adhesive backing and are easy to use.

- Superior Quality – High quality material is garanteed, close tolerance make sure the weight of the products are accurate.

- Anti-Corrosion – The surface layer of the wheel weights is first electrogalvanized, then apply multilayer and omni-dimension plastic spraying process.

- Eco-Friendly – The material of the products is lead-free, universal for 50 states.

- U.S White Tape – U.S made Four-Season Tape makes the perfect sticking results, wide paper backing disigned for easy peeling.

Last update on 2024-03-27 / Affiliate links / Images from Amazon Product Advertising API

My advice with these is first test an object with the same weight as the lightest option in the pack. If this is too heavy, there is no point in purchasing the wheel weights.

Cover the Vent

You get hoods for external vents. These are either built into the external vent or fit over it.

They are designed to allow the exhausted air to be pushed out but the location and angle of the opening make it very difficult for the wind to access the damper flaps.

A More Extreme Solution

The wind is less likely to affect a damper and exhaust system if the fan vents through the soffit simply because this is a less exposed location.

If there are other reasons to move the terminal point of the ductwork, you can consider moving it so that it vents through the soffit. The noise should be eliminated in doing so.

What if it Makes Noise Without Wind?

There can be a lot of different reasons behind a noisy fan. Since I have previously written an article about why bathroom fans get noisy I won’t go into more detail here.

I have separate articles where I discuss why range hood makes noise when it’s windy and why dryer vents make noise when it’s windy. Most of the information applies to all the systems, but if you are having trouble with a noisy range hood or dryer, head out to the other article since there are some differences.