When it comes to building code and wiring, things can seem very complicated. It’s a mess of terminology and footnotes, but thankfully, you aren’t going to have to decipher this on your own.

The cable type you should use depends on whether your basement is finished or unfinished, dry or damp. Furthermore, how you install the cables will impact how you need to protect the wiring and how you need to secure your cables and raceways.

Unfinished basements utilize NM or SE cables, which are suitable for damp locations, while finished basements can use a variety of cables (same as for the rest of the house). There are situations in which the cables require extra protection from the elements or physical damage.

Unfinished Basements

Section E3802.4 of the International Residential Code (IRC) covers the wiring regulations for an unfinished basement. It is quite the mouthful, but hopefully, you understand what the regulation is saying once you have read through the following sections.

Wiring That Does Not Require Added Protection

The initial two sentences of Section E3802.4 are the main concern when speaking of wiring that doesn’t need additional protection:

“Where Type NM or SE cable is run at angles with joists in unfinished basements and crawl spaces, cable assemblies containing two or more conductors of sizes 6 AWG or larger and assemblies containing three or more conductors of sizes 8 AWG and larger shall not require additional protection where attached directly to the bottom of the joists. Smaller cables shall be run either through bored holes in joists or on running boards.”

First, let me address the two cables (groups of wires) mentioned in the code:

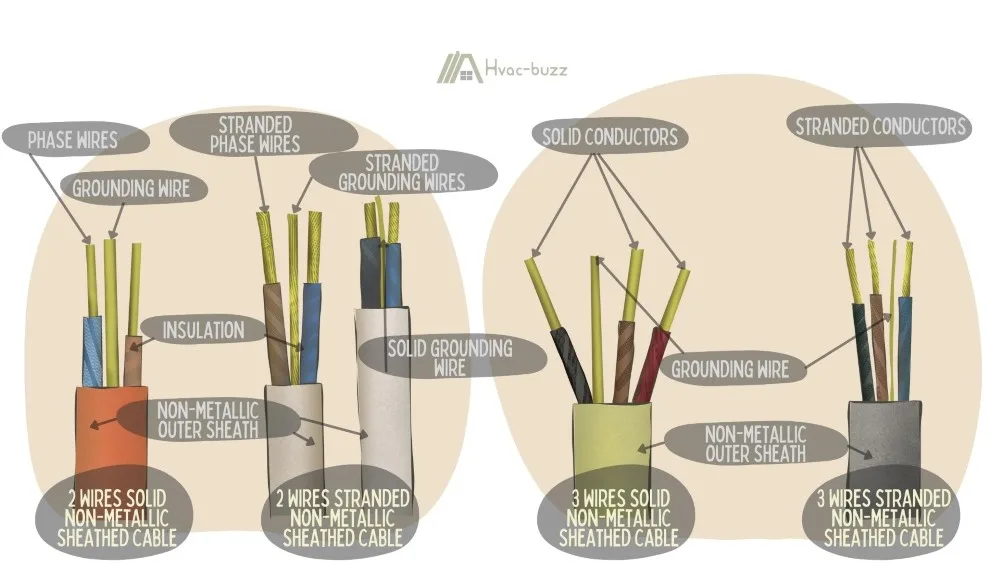

- Type NM (non-metallic) cable is comprised of insulated conductors (two or more) within a non-metallic sheathing. These are unique in their suitability for damp environments, such as an unfinished basement.

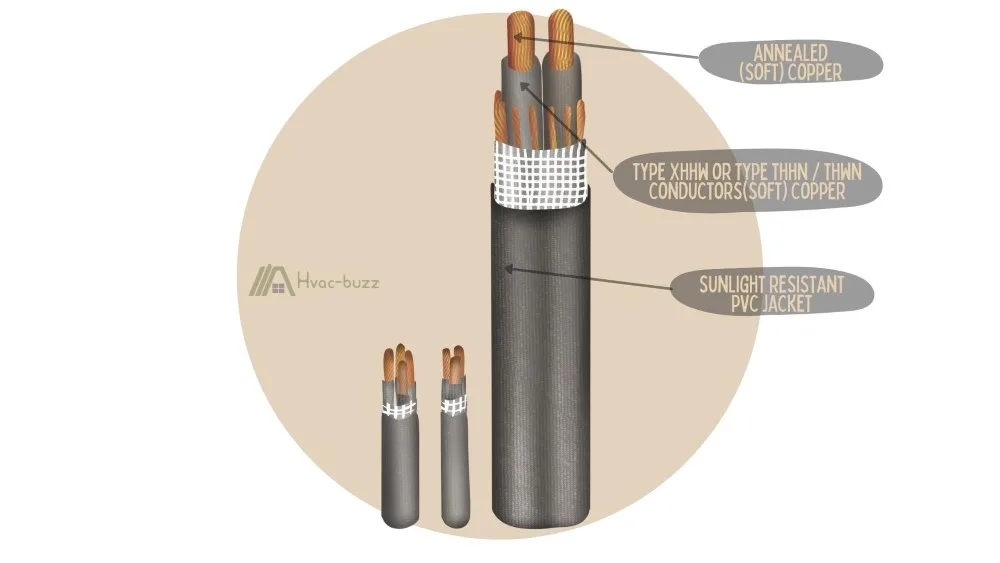

- Type SE (service entry) cable is comprised of insulated conductors that are encased in a jacket that is resistant to moisture and fire. These cables are also suitable for wet locations.

For both cable types, when running them in a basement, you must angle them across the joists, which is important for protecting the wires from damage and protecting people who enter the basement from harm.

It is also necessary to use the correct grade of cable that can withstand your basement environment. By using cables with insulation intended to protect against damp, you are reducing the risk of injury to people and damage to the house.

AWG is the acronym for American Wire Gauge and refers to wire size, excluding the insulation. For multi-strand conductors, AWG is the cross-section of all these wires added together. The lower the numbers before “AWG”, the bigger the diameter of the wire.

A cable assembly is pre-group cables of a certain orientation and length and makes installation easier.

These wires can be multi-strand NM or SE cables of a minimum of two conductors of size 6 AWG or bigger or a minimum of three conductors of size 8 AWG or bigger. You can attach these using staples or hooks at the bottom of the joists. Anything smaller must be run through drilled holes in the joists or using running boards.

These cables are fine to install and appropriate for use in your basement without any extra protective measures.

Which Wires Require Conduit Protection

Now we can discuss the rest of Section E3802.4 from the IRC:

“Type NM or SE installed on the wall of an unfinished basement shall be permitted to be installed in a listed conduit or tubing or shall be protected in accordance with Table E3802.1. Conduit or tubing shall be provided with suitable insulating bushing or adapter at the point where the cable enters the raceway. The sheath of the Type NM or SE cable shall extend through the conduit or tubing and into the outlet or device box not less than 1/4 inch (6.4 mm). The cable shall be secured within 12 inches (305 mm) of the point where the cable enters the conduit or tubing. Metal conduit, tubing, and metal outlet boxes shall be connected to an equipment grounding conductor complying with Section E3908.14. [334.15(C)]”

If you plan to run your cables along the walls of your unfinished basement instead of across the joists, you will need to provide additional protection for your wiring.

Raceways or Sleeves

Between the connection points at either end of the cables, you will need to provide conduit or tubing. These raceways are going to insulate the cables further and keep them off potentially damp walls.

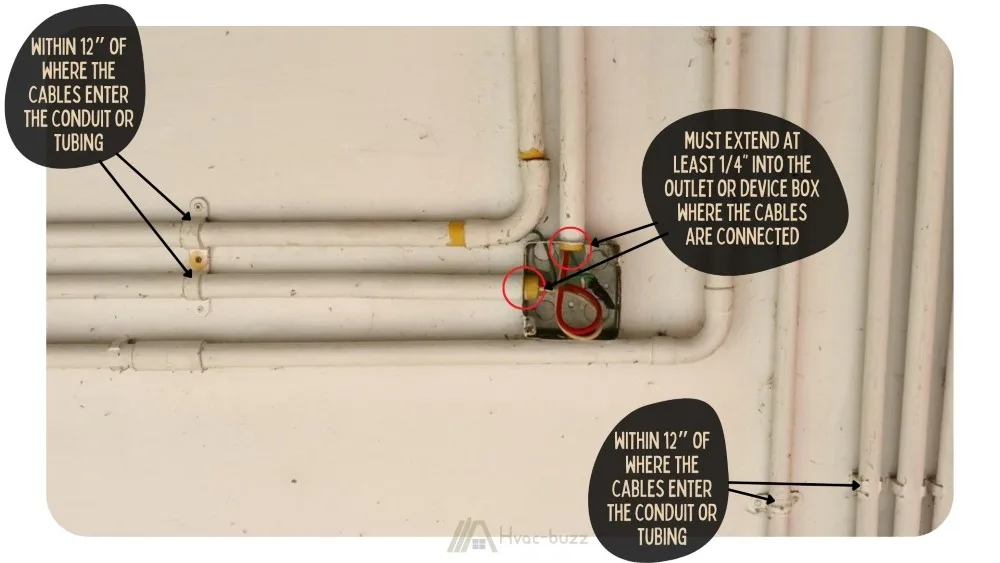

Anchoring

Where the cables enter the raceway, you will need to anchor the wiring. This must be done within 12” of where the cables enter the conduit or tubing. And the actual sheath of the cable must at least extend 1/4″ into the outlet or device box where the cables are connected.

Insulating Bushing or Adapter

Insulating bushing is a ring that fits around the end of conduit or tubing, where the wires enter and protects the cables from the tough casing. An insulated adapter performs the same function.

Grounding

Lastly, it is important to ground any metal elements of the wiring system. Electrical wires are involved, and you need to protect against electrocution and fire hazards should any of the wires become damaged and/or exposed.

I have written an article dedicated to basement wire conduiting if you are looking for more details.

Raceways in Cold or Humid Basements

According to Section E3802.7 (IRC), when you have a temperature fluctuation along the length of your raceway or sleeve, you have to seal it with an approved material to prevent the different temperatures from interacting.

An approved sealant will be listed for use with terms such as “conductor insulation”, “cable insulation”, or “shield”. This will ensure that the sealant can perform the function of keeping any warmer air away from the colder air.

The main issue with the mixing of cold and warm air is condensation. With condensation, there may be issues of moisture gathering inside the casings or insulation of the cables. This is dangerous if there is water touching electricity and can damage the wiring system, the house, and can be hazardous to your household.

Unfinished basements are particularly prone to temperature differences, and where your cabling passes above the grade plane may also be vulnerable to condensation.

Rules Regarding Exposed Cables

There are two main rules for exposed cables in an unfinished basement, as per Section E3802.3 of the IRC. And they are intended to protect the cables in the stead of an enclosure.

Cable assemblies must have a surface installation. This means your cables must be installed close to the level of finish in the house (this would be the ground floor) or the running boards.

Where exposed cables may be vulnerable to physical damage, protection is required. This must be an approved means of protection, such as:

- Schedule 80 PVC conduit.

- A rigid or intermediate metal conduit (this will need to be grounded).

- Electrical metallic tubing (requires grounding).

- RTRC-XW (fiberglass conduit).

And these means of protection must extend at least 6” above the floor where the cables are running through the floor.

Raceways in Damp Daylight or Walkout Basements

When using raceways in a damp daylight or walkout basement, the IRC (Section E3802.8) states that the inside of the sleeve is regarded as a wet location. So, your insulated conductors, as well as your cables, all need to be listed and labeled for use in wet locations.

Raceways in these forms of basements can still suffer from differences in temperature that can often accompany dampness. The basement is more likely to be cold or humid if there is moisture in the area. The raceways will need to be insulated to protect against warmer air entering sections with colder air.

Finished Basement

This section will cover the installation requirements for wiring in above-ground areas, which is what a finished basement is considered. This information is from Table E3802.1 in the IRC.

The following tables contain the electrical conductors (or cable types) and the requirements that apply to each.

| AC/MC |

| Wiring must be within 1¼” of the framing member (i.e., joist) or furring strip where it runs parallel to these, or it requires physical protection. |

| Holes bored into the framing member must be at least 1¼” from the edge or require listed physical protection (i.e., steel plate/sleeve with minimum 0.0625” thickness). |

| Listed steel plate (0.0625”)/equivalent is required where the cable (or raceway) is installed in a groove that will be covered by a finish (i.e., panel or carpeting). Alternatively: a minimum of 1¼” free space for the full length of the groove is required. |

| Bushings are required where wires enter any enclosure/box/fitting unless it’s designed to provide equivalent protection. |

| Maximum spacing between cable supports: AC: 4.5 ft MC: 6 ft Note: supports are not required between light fixtures where the length is a maximum of 6 ft and they are in an accessible ceiling. |

| Maximum distance between supports and junction boxes/termination points: 12” AC: 25” Interlocking MC that needs flexibility: 36” Note: supports are not required between light fixtures where the length is a maximum of 6 ft and they are in an accessible ceiling. |

| EMT/IMC/RMC |

| Maximum of four bends of 90° in between junction boxes. |

| Bushings are required where wires enter any enclosure/box/fitting unless it’s designed to provide equivalent protection. |

| Ream ends of raceways to smooth the edges and protect cables. |

| Maximum spacing between cable supports: 10 ft |

| Maximum distance between supports and junction boxes or termination points: 36” |

| ENT |

| Wiring must be within 1¼” of the framing member (i.e., joist) or furring strip where it runs parallel to these, or it requires physical protection. |

| Holes bored into the framing member must be at least 1¼” from the edge or require listed physical protection (i.e., steel plate/sleeve with minimum 0.0625” thickness). |

| Listed steel plate (0.0625”)/equivalent is required where the cable (or raceway) is installed in a groove that will be covered by a finish (i.e., panel or carpeting). Alternatively: a minimum of 1¼” free space for the full length of the groove is required. |

| Secure, protective grommets/bushings are required where wiring runs through openings in metal framing members. |

| Maximum of four bends of 90° in between junction boxes. |

| Bushings are required where wires enter any enclosure/box/fitting unless it’s designed to provide equivalent protection. |

| Ream ends of raceways to smooth the edges and protect cables. |

| Maximum spacing between cable supports: 3 ft Note: supports are not required between light fixtures where the length is a maximum of 6 ft and they are in an accessible ceiling. |

| Maximum distance between supports and junction boxes/termination points: 36 ft |

| FMC/LFC |

| Wiring must be within 1¼” of the framing member (i.e., joist) or furring strip where it runs parallel to these, or it requires physical protection. |

| Holes bored into the framing member must be at least 1¼” from the edge or require listed physical protection (i.e., steel plate/sleeve with minimum 0.0625” thickness). |

| Listed steel plate (0.0625”)/equivalent is required where the cable (or raceway) is installed in a groove that will be covered by a finish (i.e., panel or carpeting). Alternatively: a minimum of 1¼” free space for the full length of the groove is required. |

| Maximum of 4 bends of 90° in between junction boxes. |

| Bushings are required where wires enter any enclosure/box/fitting unless it’s designed to provide equivalent protection. |

| Ream ends of raceways to smooth the edges and protect cables. |

| Maximum allowed spacing between cable supports: 4.5 ft Note: supports are not required between light fixtures where the length is a maximum of 6 ft and they are in an accessible ceiling. |

| Maximum distance between supports and junction boxes or termination points: 12 ft Flexible conduit can be used if it doesn’t extend more than the following dimensions beyond the last attachment point of the raceway: Sizes ½ to 1 ¼: 36” Sizes 1 ½ to 2: 48” Sizes 2 ½ and larger: 5 ft Note: supports are not required between light fixtures where the length is a maximum of 6 ft and they are in an accessible ceiling. |

| NM/UF |

| Wiring must be within 1¼” of the framing member (i.e., joist) or furring strip where it runs parallel to these, or it requires physical protection. |

| Holes bored into the framing member must be at least 1¼” from the edge or require listed physical protection (i.e., steel plate/sleeve with minimum 0.0625” thickness). |

| Listed steel plate (0.0625”)/equivalent is required where the cable (or raceway) is installed in a groove that will be covered by a finish (i.e., panel or carpeting). Alternatively: a minimum of 1¼” free space for the full length of the groove is required. |

| Secure, protective grommets/bushings required where wiring runs through openings in metal framing members. |

| Maximum spacing between cable supports: 4.5 ft Note: flat cables must be stapled flush. |

| Maximum distance between supports and junction boxes/termination points: 12 ft (within 8” of boxes and without clamps for the cable.) Note: Flat cables must be staples flush. |

| RNC/RTRC |

| Maximum of four bends of 90° in between junction boxes. |

| Bushings required where wires enter any enclosure/box/fitting unless it’s designed to provide equivalent protection. |

| Ream ends of raceways to smooth the edges and protect cables. |

| The maximum allowed spacing between cable supports: 3 ft Sizes 1 ¼ to 2: 5 ft Sizes 2 ½ to 3: 6 ft Sizes 3 ½ to 5: 7 ft Size 6: 8 ft |

| Maximum distance between supports and junction boxes/termination points: 36 ft |

| SE |

| Wiring must be within 1¼” of the framing member (i.e., joist) or furring strip where it runs parallel to these, or it requires physical protection. |

| Holes bored into the framing member must be at least 1¼” from the edge or require listed physical protection (i.e., steel plate/sleeve with minimum 0.0625” thickness). |

| Listed steel plate (0.0625”)/equivalent is required where the cable (or raceway) is installed in a groove that will be covered by a finish (i.e., panel or carpeting). Alternatively: a minimum of 1¼” free space for the full length of the groove is required. |

| Secure, protective grommets/bushings required where wiring runs through openings in metal framing members. |

| Maximum spacing between cable supports: 2.5 ft Service/outdoor feeder: 2.5 ft Branch circuit/indoor feeder: 4.5 ft |

| Maximum distance between supports and junction boxes/termination points: 12 ft |

| SR (Note: IRC indicates that manufacturer directions shall be followed for installing this cable.) |

| Listed steel plate (0.0625”)/equivalent is required where the cable (or raceway) is installed in a groove that will be covered by a finish (i.e., panel or carpeting). Alternatively: a minimum of 1¼” free space for the full length of the groove is required. |

| Bushings required where wires enter any enclosure/box/fitting unless it’s designed to provide equivalent protection. |

| Ream ends of raceways to smooth the edges and protect cables. |

| USE |

| Listed steel plate (0.0625”)/equivalent is required where the cable (or raceway) is installed in a groove that will be covered by a finish (i.e., panel or carpeting). Alternatively: a minimum of 1¼” free space for the full length of the groove is required. |

| The maximum allowed spacing between cable supports: 2.5 ft |

Basement Outlets

To wire your basement appropriately, you also need to know about the different regulations for receptacle outlets in finished and unfinished basements. There are different locations that require outlets, or where they are prohibited. You can look at this comprehensive guide for outlet positioning in basements to find a detailed breakdown of the IRC regarding outlets and protective measures.

Sources

https://www.nachi.org/conductor-types.htm

https://www.dli.mn.gov/sites/default/files/pdf/eli_bulletin_cable.pdf

https://ewcswire.com/blog/common-6-awg-wire-applications/

https://sawmillcreek.org/showthread.php?233550-How-to-run-6-wire-across-my-basement-joists

https://www.elandcables.com/the-cable-lab/faqs/faq-what-are-cable-assemblies