Drylok is warrantied to last between 7-15 years. After this period, it might start to crack or peel off. The absence of this protective layer could encourage the growth of mildew, mold, and bacteria, as well general damp, all of which affect the aesthetics and structural integrity of a building. Not to mention the mold-related health issues!

This is a guide through the process of preparing, patching, and finally, applying Drylok on new or old masonry surfaces that were previously painted with Drylok.

Drylok can be applied over old Drylok only if the old layer is not peeling. For Drylok to act as an effective waterproofer, it must penetrate into the pores of a surface. Once Drylok starts to peel, it becomes ineffectual and has to be removed.

Always Prep the Surface for Drylok Application

Typical Preparation Steps

Before applying Drylok to any surface, you must first ensure that the surface is clean and dry. They should not have any dust, dirt, grease, oil, efflorescence, and loose Drylok on them. You should use a wire brush for removing these particulates and then finish up with a shop vacuum if the brush doesn’t get the job done.

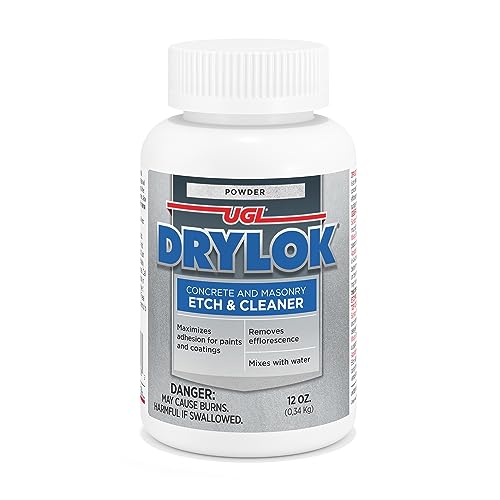

In a situation where there is stubborn efflorescence that cannot be removed with a wire brush, an acid clean would have to be done. You can either use Drylok Etch or muriatic acid.

Efflorescence is a powdery crystal-like deposit that appears on concrete, brick, or masonry due to the presence of soluble salt and moisture.

- MASONRY ETCH & CLEANER - Highly effective in etching. It removes unsightly efflorescence (salt deposits) as well as excess mortar.

- USE - It is perfect for treating smooth concrete and condition galvanized surfaces prior to painting.

- COVERAGE - 300 square feet per 12 ounce container when used as a cleaner. 150 square feet per 12 ounce container when used as an etch.

- IDEAL - For removing efflorescence and excess mortar build-up on tile, galvanized metal, stone, concrete and brick

Last update on 2024-03-27 / Affiliate links / Images from Amazon Product Advertising API

Drylok is usually difficult to remove with a wire brush or putty knife. So, for large areas like a basement, a pressure wash is the best way to get peeling Drylok off.

If the wall has cracks or holes, fill up the space with a fast-setting hydraulic cement or Drylok Fast Plug (which requires 3-5 minutes to set before being painted over).

Don’t ignore the floor and wall joints during this process.

If your building is experiencing water leakage, you should discover and fix the source of the leakage before applying new coats of Drylok.

Reasons for This Preparation

A properly prepped wall is easy to work with and it’s a fail-proof way to avoid wasting your efforts and resources.

Drylok has waterproofing abilities. For its elements to function effectively, they need to penetrate into the pores of a surface.

- Loose dirt, paint, etc., prevent Drylok from adhering firmly to a surface. Peeling Drylok is not only ugly, but it’s also useless. Moreover, the old Drylok prevents the new coat from bonding to the wall. So, the new coat will be loose and quickly peel off just like the old coat. The composition of efflorescence also prevents Drylok from adhering to a surface.

- Cracks and holes are defects that should be corrected because they can grow into bigger structural issues. And because Drylok cannot be applied into holes, your building will be left vulnerable to moisture penetration.

After prepping the surface, leave it to dry for at least 24 hours. If it’s an indoor project, open windows for improved ventilation and employ a fan or dehumidifier to speed up the process. This is important because Drylok cannot adhere to saturated walls.

Paint Over Remaining Drylok

After you’ve prepped the wall, you can proceed to paint the new Drylok on (go for a tinted Drylok to make your basement walls look more exciting). Any old Drylok that is still adhered to the wall after the above steps is safe to paint over. However, if you notice any lingering loose Drylok before you start painting, you’ll have to get it off before you proceed.

Any new coat that is placed on loose Drylok is just a painting without waterproofing qualities.

Use a minimum of two coats of Drylok. Apply the first coat with a good quality nylon bristle brush or a Drylok brush so that the Drylok sinks into the pores of the surface. Leave the coat to dry for at least 3 hours, and then apply the second coat.

- 4" Synthetic bristle brush

- Chiseled tip helps achieve professional-looking results

- Extra-firm bristles ensure maximum coating

- Reusable

Last update on 2024-03-27 / Affiliate links / Images from Amazon Product Advertising API

The composition of Drylok Extreme is perfect for demanding conditions, so it’s the best choice for application over Drylok.

The main difference between Drylok original and Drylok Extreme is that Drylok Extreme has better water resistance.

It is important to note that Drylok shouldn’t be applied during rainy or humid climates to ensure maximum results.

Take a Detour

Can Drylok Be Sprayed (Tips to do it safely)

Is the Area Small Enough to Patch?

Does the whole surface need to be repainted with Drylok or can you get away with a few patches? This could save you a whole lot of money and time.

Drylok Fast Plug is one of the most popular patching solutions. It is a hydraulic cement, designed to seal holes and cracks in masonry structures or concrete. It prevents active or recurring water from flowing through the holes and cracks.

- Set time: 3-5 minutes

- Stops water, even under pressure

- Anchors metal to masonry

- Not top coat required

Last update on 2024-03-27 / Affiliate links / Images from Amazon Product Advertising API

To apply Drylok fast plug on active leaks:

- Mix the appropriate amount of fast plug and water until it becomes warm to touch.

- Next, force the mixture into the surface and hold it in place for 3-5 minutes so that the paste properly sets and bonds with the wall.

- After that, smooth the patch evenly with surrounding surfaces.

Note that Drylok fast plug sets within 3-5 minutes, so only mix enough to use at once.

For inactive leaks, patching, and anchoring, follow the same steps but use a chisel to form the shape of an inverted V before forcing the mixture into the surface. This allows the patch to bond with the surface and also cure properly.

For smaller cracks, you can use products that are applied with a nozzle or caulk gun like Drylok Pourable Masonry Crack Filler (amazon link).

The cement-like color of Drylok Fast Plug might not blend with the existing decor and might have to be painted over.

Before painting over Drylok fast plug, set the area with either Drylok Powdered Basement & Masonry Waterproofer, Drylok Original basement and Masonry Waterproofer or Drylok Concrete Floor Paint.

Changing the Color of Your Drylok

Most Drylok waterproofers feature a few mild tint pallets. To tint Drylok before application, use an alkali-proof universal tinting colorant. Some home improvement stores provide pre-tinted paint options.

A major concern of people who would like to change the color of a functional Drylok coat is that the paint might interfere with the moisture blocking abilities of Drylok.

After it is completely dry, It’s safe to paint Drylok with a latex or acrylic paint. A primer isn’t required because Drylok serves as an ideal base coat. For new Drylok projects, it is best to wait for at least 24 hours before applying paint over Drylok.

For older Drylok you should ensure that the room isn’t humid before painting.

If an enamel or water-based paint is used, it can tamper with the waterproofing functions of Drylok.

How Do You Remove Old Drylok?

To effectively remove Drylok from a surface, you will need:

| Tools | Amazon link |

| Safety goggles | View |

| Gloves | View |

| Solvent (talk to someone at your local hardware store for a product that acts on the resistant Drylok) | |

| Putty Knife | View |

| Bristle brush | View |

| Sander | View |

| Pressure washer | View |

The composition of Drylok solvents could affect the eyes and skin. So ensure that you’re wearing safety goggles and gloves.

- Use a sander to make the surface more porous.

- With a bristle brush, apply the solvent on the Drylok and allow it to sit for at least 45 minutes.

- After that, set the pressure washer to top pressure and wash off as much Drylok as you can.

- If there is still Drylok left, use a putty knife to remove chunks from the wall.

- Repeat the above steps until you are satisfied that all the Drylok has been removed.

Note that using a pressure setting that’s above 1750 psi can cause damage to concrete.

Source

https://www.insofast.com/media/Drylok-Masonry.pdf

https://www.dulux.com.au/applicator/technical-advice/performance/efflorescence

https://images.homedepot-static.com/catalog/pdfImages/7b/7b5e969d-0128-47f1-abe7-989717b7d879.pdf

https://homeguides.sfgate.com/prep-walls-drylok-70534.html

https://images.homedepot-static.com/catalog/pdfImages/ae/aec1d182-96f6-49a3-bdcc-6dfc1218919e.pdf